What do you understand by 'hygiene'? It's a broad concept, so numerous answers are possible. However, the lack of a clear definition in the design and construction of machinery can have significant consequences, raising risks to food safety.

Hygienic Design needs greater emphasis. Particularly, the connection between technology and its practical application deserves more attention. When designing equipment for the food industry, it's crucial that a purchaser clearly defines their expectations regarding hygiene, and that the equipment supplier clearly outlines the limits for intended use.

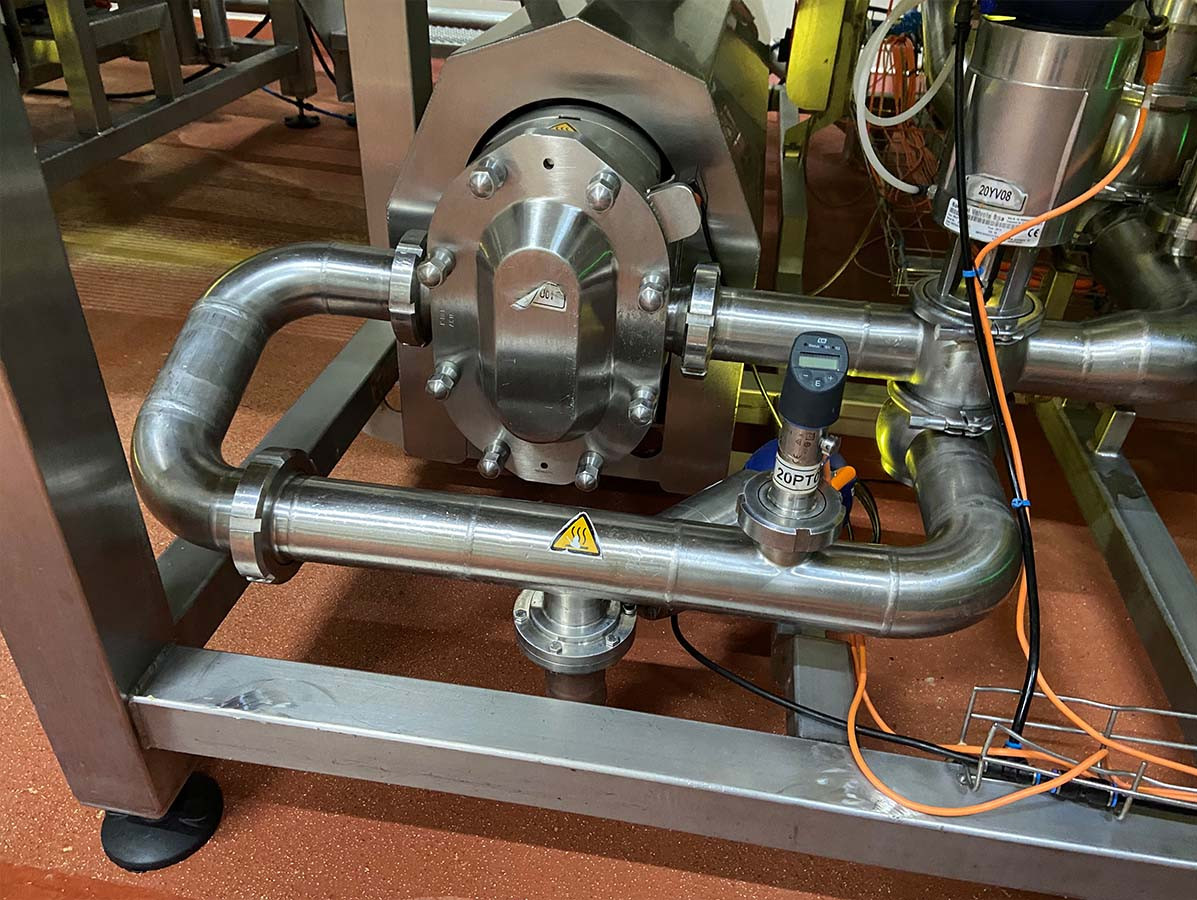

The photo shows an Incorrect placement of the pump. It should have been rotated a quarter turn so that the pipes are vertical. Only then is drainage ensured. This is wrong in 80% of cases.

Assumptions are dangerous for both parties in all cases, especially concerning liability. Technology often does not align seamlessly with application requirements. The significant language difference between machine builders and suppliers on one hand, and equipment users in the food industry on the other, complicates matters. Variations in professional jargon, non-standardized symbols, lack of instructions, differing interests; the causes for miscommunication are diverse and extensive. Causes can be summarized as 'incomplete information transfer and insufficient knowledge'. The solution to prevent problems seems simple: formulate the right principles and exclude assumptions and misinterpretations.

Realize that designers or builders of machines or installations may not always be aware of all risks in the respective production process. This can easily occur if they lack direct contact with end-users, or because relevant information is simply not available to them. Therefore, it's useful to establish a hypothetical situation in the design phase where the limits of intended use and cleaning conditions are clearly defined. A machine or installation not designed for in-line cleaning (CIP) cannot be used for that purpose. Despite seeming logical, this often goes wrong. There's frequently confusion about how something should be cleaned, whether it can be, and how it's done. This lack of coordination between machine builder and user is the reason for much misplaced use. A consequence is that components are not properly cleaned, directly affecting food safety. Residual dirt in the form of bacteria, allergens, or cleaning agents can contaminate a new production batch.

This photo shows a correct setup.

A starting point in designing is the EN1672-2 standard. It refers to a Hygiene Risk Analysis (HRA), equivalent to a RI&E for safety, but for hygienic risks. An HRA is conducted before a design is made. The outcome is a list of measures to be taken to eliminate or reduce risks to an acceptable level. These measures include aspects in design, technology, cleaning, and additional instructions, creating an optimal starting situation for setting up design, technical, cleaning, and instructional measures. Along with the usual PFD, layout, and functional description, an HRA forms the basis for a good design. Before actual construction, an interim evaluation takes place: the HYHAZOP. This can occur simultaneously with the usual HAZOP. Adjustments can still be made at this stage. Additionally, suppliers are obliged to explicitly warn about any residual risks.

The HDN platform, with various working groups, has established 'Best practices'. Through various courses, offered by HDN itself or via external institutions, the organization provides tools for and recognition of the necessary craftsmanship. Demonstrability of GMP (Good Manufacturing Practice) is a legal requirement (European regulation EC2023), but also a GFSI requirement for HACCP. The HDN methodology enables this GMP: for suppliers, but also for food producers.

Source: vakblad Voedingsindustrie 2023