Huuskes is a leader in the field of food and drink in the care and catering sector. Their credo: 'listening well to the customer and acting accordingly'. They are doing so quite successfully: "We are growing continuously," says Frank Hagmolen, chief technical officer.

Huuskes was founded in 1956 by Henk Huuskes senior. With his delivery van he drove to border stores and care centers in the region to sell processed meats and various frozen products. The company soon expanded. More departments were added. A greengrocer, butcher and poulterer joined the company. The company supplied more products to hospitals and care centers. Cooking was first done by the hospitals themselves, until they indicated that they preferred to let Huuskes do the cooking. In 1993 complete meals were prepared and delivered by Huuskes cooks. Customers back then, as well as today, liked to see one overall supplier.

The head office - with all the production departments and a logistics center - is in Enschede. In Oldenzaal and Winschoten, special meals are prepared, such as gluten-free and pasta. Distribution centers are located in Winschoten, Nijkerk and Beuningen. "The building in Enschede is on a relatively small industrial estate, on the edge of a residential area. In the past, there were doubts about this location. The future of the company required expansion; could it happen here? Nevertheless, we stayed. We now have several tens of thousands of meters of production floors," says Frank.

Frank Hagmolen (left) and Hendrik Ruys

At the entrance in front of the production hall is a model that illustrates the size of the company. During the tour, however, we soon lose track. A multitude of rooms and departments follow: for packing orders, the vegetables, cutting the meat, the poulterer, cooking the meals. Half an hour later, this turns out to be only half of the business. Frank: "We are constantly on the move. Now we are working on a second cooling tower, for which we have removed some walls." Those who look very closely can see this on the floor, which is missing at the level of the former walls. "This will soon be repaired by the Ruys Group. We have been working with them for more than 20 years. Walking through the building, you can't tell which floors are 20 years old, and which are 2 years old. They remain beautiful and functional.''

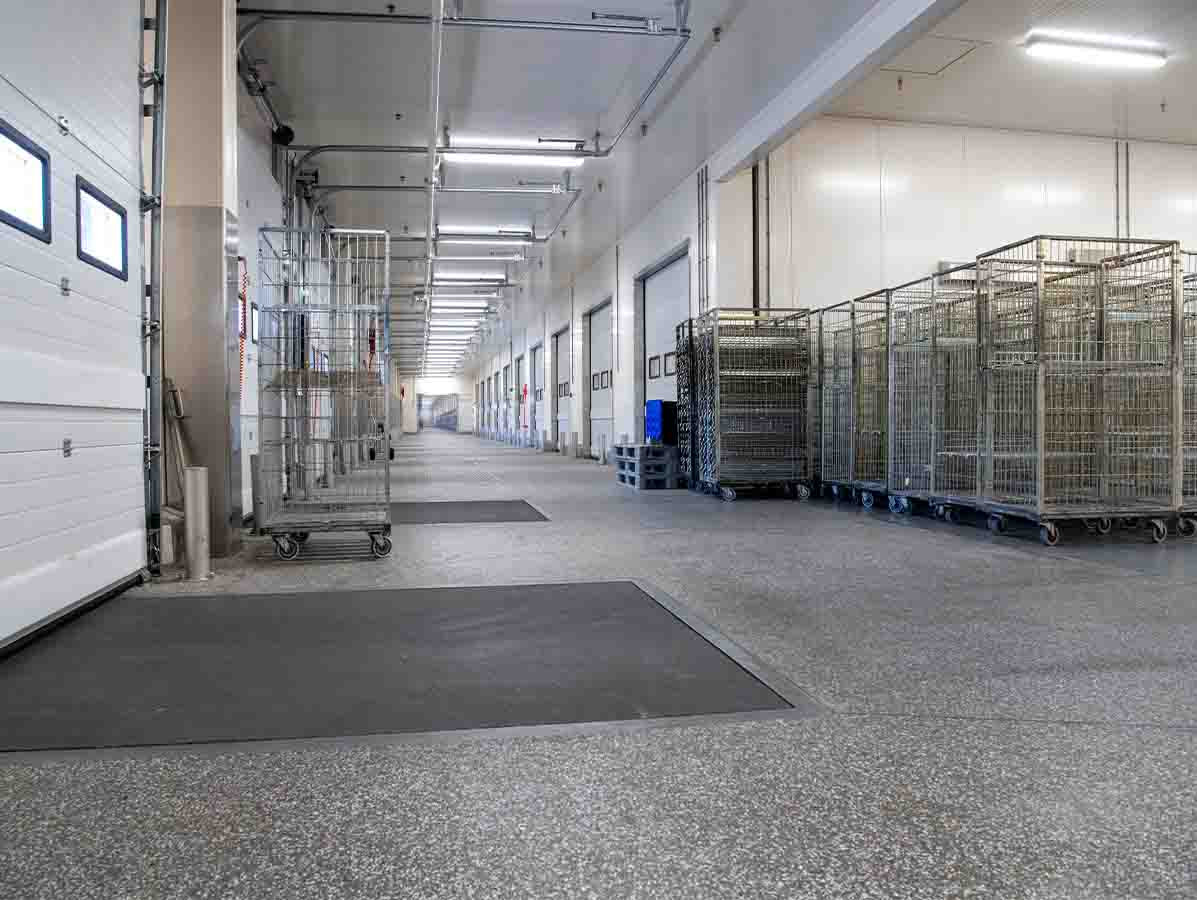

Director Hendrik Ruys of the Ruys Group (including Ruys Vloeren, SR Vloeren, De Bedrijfsvloer & RS Maatwerk) knows his way around Huuskes well. The company has several industrial floors from the Ruys Group; specialists in granite floors for the food industry. Hendrik says he has supplied floors for eighty percent of Dutch meat companies. "Floors where meat is processed must have good anti-slip because they are often wet. For that, the Margia Granite floor is very suitable. That is installed here as well, at Huuskes. The Margia Stone is used where there is a lot of transport: in cold stores, shipping and order picking. This floor is very resistant to intensive traffic, sliding loads and daily cleaning." In renovations, Ruys mainly applies the Ucrete floor. "This is resistant to high and low temperatures and strong acids, but above all it can be used very quickly. That makes it ideal for this industry. After all, production has to go on."

At Huuskes, we also see the MARGIA CRETE renovation floor, which combines properties of the Margia Granite and Ucrete. In the toilets and locker rooms there are plastic trowel and cast floors. "We have been offering these for about ten years now through our subsidiary De Bedrijfsvloer," says Hendrik. "The right floor in the right place is our slogan."

©Eric Brinkhorst

Frank is satisfied with Ruys' floors. "They last a long time. If a repair is needed, they have no problem coming back over the weekend so we can just run again on Monday. They are happy to think along with us." Hendrik: "We look at what is being processed in the space, what processes are taking place and what the load is. That's how we come up with the best floor solution." In addition to the floor type, the slope and risers are also important. "We make floors where you don't feel the slope, but it works: no puddles remain on the floor. We can give that assurance," says Hendrik. The risers are fitted with stainless steel. "Before, they were made of concrete," Frank looks back. "But everything here has to be idiot-proof. This is reflected in the concrete edges: they splinter off. The stainless steel bumpers stay nice, even if people bump into them."

Another meeting between Ruys and Huuskes is planned in the near future: expansion is already being considered. "We have entered into a partnership with Chef Culinar," says Frank. " We want to use this to serve the German market even better in the future."

www.huuskes.nl

www.ruysgroep.nl

Text and photos: Naomi Heidinga

Source: Vakblad Voedingsindustrie 2023