The factory has been located in Giessen since it was founded, the apple sauce is still in great demand and the quality is consistently high. But a lot has changed at HAK. Recently, a new pouch line was introduced, for which substantial rebuilding was required.

After thirty years of trading vegetables and potatoes, the HAK grocer family wanted to process products on a large scale. Thus, in 1952 a modest canning factory was set up in Giessen, a village in the countryside of Heusden and Altena. The well-known HAK glass pot was developed back in 1964, because glass is hygienic and taste-neutral. Over time, numerous developments took place: takeovers, mergers and there were even reorganizations sometimes. The range of products was greatly expanded. In order to place the maximum focus on the HAK pot, the company stopped producing private labels in 2012. HAK is now one of the largest fruit and vegetable processing companies in Northern Europe. Most of the raw materials come from the Netherlands; the HAK fields are usually no more than 125 kilometers from the factory.

“Sustainability is an important theme for HAK”, says Production Director Koos van Leeuwen. “Just like health”, he continues. “We have great ambitions in that area. We want to be more than a canning factory. Our aim is to become a ‘healthy food factory’ by 2021. We will continue to offer popular products such as apple sauce and red cabbage, but the emphasis will be on vegetables and legumes in as pure a form as possible. HAK recently acquired the company Peter van Halder, a specialist in chilled vegetables. And we are constantly working to reduce or completely remove sugar and salt from our products.”

With its focus on healthy products, HAK expects to appeal to a broad target group and meet the growing demand for alternative protein sources for meat. Van Leeuwen says: “In order to contribute to a healthy diet, HAK has gradually expanded its range of legumes since the end of 2015. We now have, for example, black beans, lentils, chickpeas and various mixes with legumes. The beans are already cooked, contain hardly any moisture and can be used hot or cold. We also launched meal solutions, including soups with beans and dishes such as curry and roti.”

In addition to the well-known HAK pot, there will be an innovative and easy to handle packaging: the pouch. Van Leeuwen: “The new legumes were processed, prepared and packaged in a different way and a new sauce line had to be created. The beans are prepared and preserved once they are in the bag, not before. This way they keep a delicious crunchy bite. A precarious and innovative way of working.”

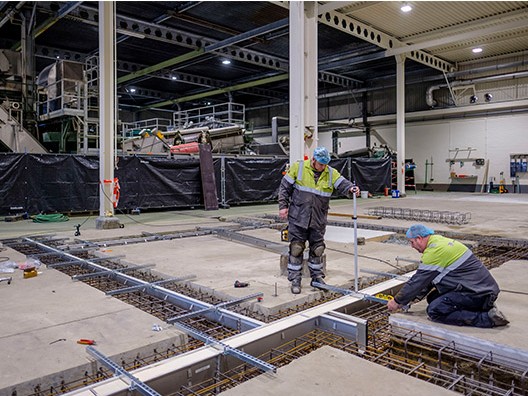

The new pouch line required a major renovation, for which an existing hall was partly cleared. The hall was officially opened on 14 September 2018. An important part of the renovation was the placement of new drainage channels. “If this is not done properly, the gutters, floor and thus the entire hall can become a source of bacteria. Then food safety will be at risk,” says Van Leeuwen. Dubbelman en Zonen, the concrete and metal company that was responsible for the installation of the Ucrete floor during the renovation, asked for the installation of gutters from Blücher, specialist in drainage solutions. “We make gutters and drains for food producers, in standard sizes and to customer specifications,” says Eveline Bruins, Benelux sales manager at Blücher. The company – which is originally Danish – supplies high-quality stainless steel gutters and manholes worldwide. “Often a neglected issue in construction,” says Van Leeuwen.

Bruins agrees on the importance of good gutters for hygiene: “And good gutters reduce water usage, chemical usage and cleaning time. If there are no solid gutters, you risk having to stop production. That costs serious money. In the converted hall of HAK there are Blücher gutters, suitable for the drainage of water and finely meshed debris. They are covered with the hygienic pro gratings, which – thanks to their round shapes – are very easy to clean and therefore prevent bacterial growth. “When renovating within an already existing situation, there are always restrictions on the installation of gutters and wells. This should never be at the expense of the result. We always choose the best solutions in proper consultation with our client,” says Bruins. Van Leeuwen confirms this. “Like HAK, Blücher attaches great value to quality, hygiene and innovation. And this is shown in the outcome.”

Source: Beeld: © Roel Dijkstra persfotograaf