Curious how steam can make your production run more smoothly and keep quality consistent? In our FAQ, Scharff Techniek answers the most important questions about the benefits of steam, choosing the right boiler, and maintenance.

Steam can easily be used across multiple steps in your production process, such as pasteurising, sterilising, heating, and cleaning. It transfers heat quickly and evenly. By fine-tuning the steam pressure, that heat reaches every part of your process. This helps prevent large temperature differences and ensures your product maintains the same quality throughout.

Maintaining stable pressure and temperature allows each batch to follow the same procedure. At Scharff Techniek, we tailor the boiler to match your production volume, so the system adapts to fluctuations without compromising on hygiene or flavour.

Over time, scale and rust can form in any steam system. That slows things down and may damage components. To prevent this, regularly blow down the boiler, monitor water quality, and top up the softening salt. For added peace of mind, Scharff Techniek offers maintenance contracts that include an annual inspection for major servicing.

In the boiler, water is heated with gas, oil, or electricity until it turns into steam. The steam then transfers heat via piping to equipment like your cooking kettle, smokehouse, pasteuriser, or cleaning unit. The condensate flows back into the tank and is reheated. This lets you reuse residual heat, reduce water use, and work more energy efficiently.

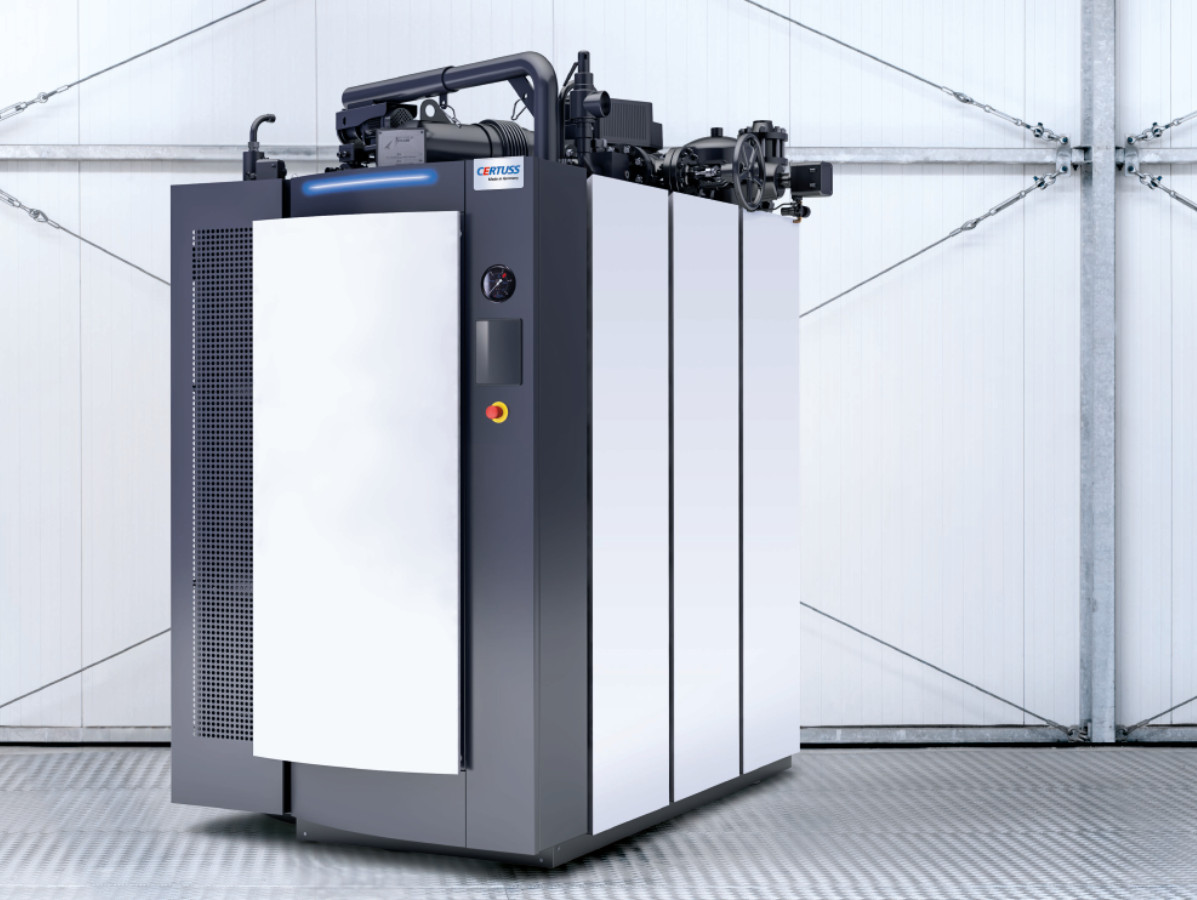

Start by determining the pressure and volume of steam you need, and how much space you have available. Do you use green electricity and have sufficient capacity? Then an electric boiler is a sustainable option. For smaller-scale operations, compact steam generators may be a good fit. Check our steam table for an overview of the right pressure–temperature combinations, or get in touch with us for a no-obligation consultation.

Source: Scharff Techniek