An efficient production line is almost impossible without an automatic checkweigher. If a product does not have the correct weight, it is rejected, preventing underfilling or overfilling.

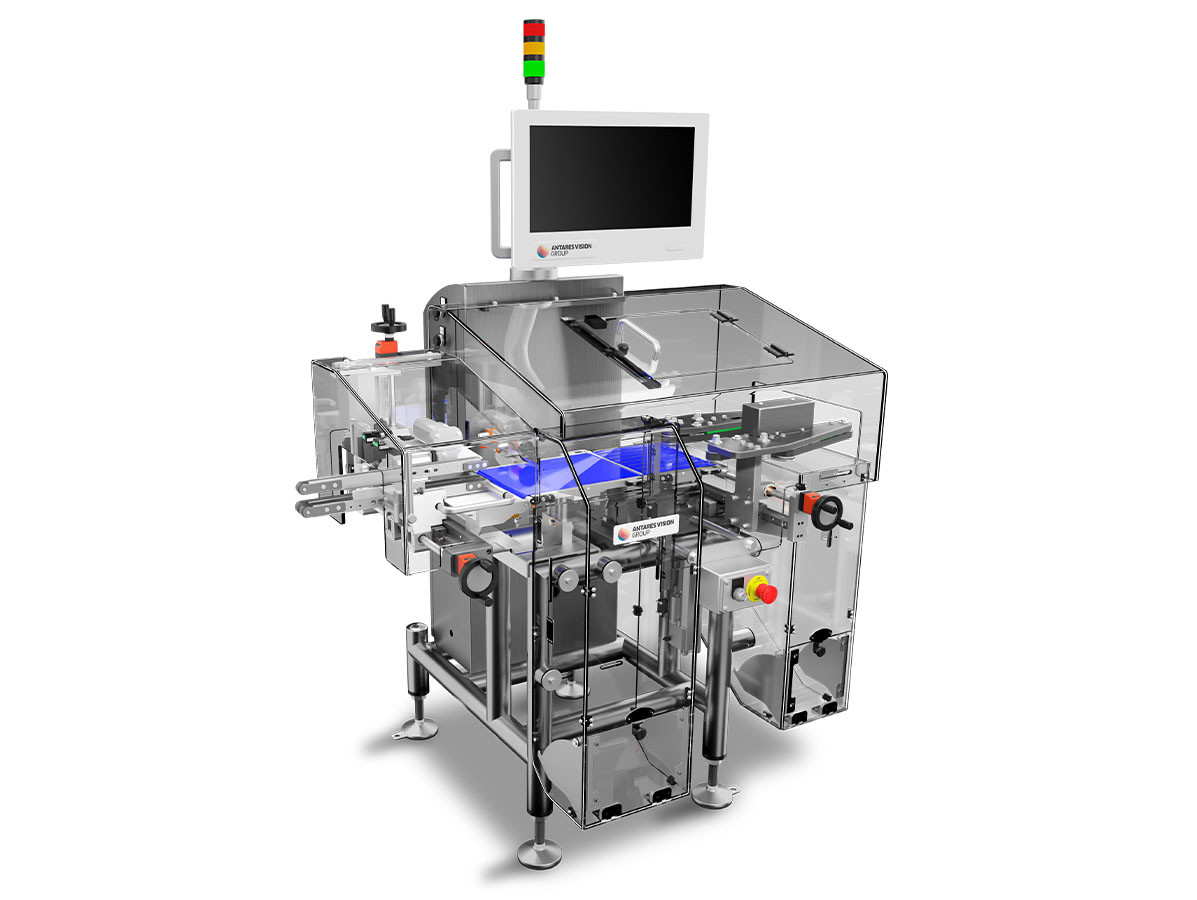

Mundi Technology's checkweighers can also be connected to your filling installation, allowing you to directly adjust the filling quantity. The machines are made of stainless steel and can be equipped with protection classes up to IP69K, depending on your needs.

Mundi's powerful checkweighers ensure accurate weight control of packaged products down to the milligram. They can be seamlessly integrated into production lines, ensuring precise dosing and safety. Our fault detection systems operate autonomously, increasing accuracy.

Incorrect labeling is an increasing risk for recalls. With our vision systems, producers opt for thorough automatic quality control. Advanced camera technology checks all labels for presence, completeness, position, and color. This ensures products with incorrect information or missing labels are removed. All types and variations of labels can be inspected, even partially or fully transparent labels are checked flawlessly.

During a production run, operators have to monitor many processes. The risk of a mistake with significant consequences is easily minimized with automatic label inspection. If the expiration date is missing, the label is skewed, the label does not match the product, or the label is missing, the product is rejected while production continues. The smart vision detects all deviations, ensuring complete quality control of products and packaging.

Multiple technologies can be combined into one system, such as shape control, leak detection, seal inspection, and label inspection. Everything can be seamlessly integrated, guaranteeing the quality of every final product. No more unnecessary product recalls and always the best quality products for your customers through fully automatic inspection of all labels. A combination with leak detection and seal inspection is possible.

With improved accuracy, efficiency, and reliability, you reduce costs, improve regulatory compliance, and protect your brand reputation.

Visit www.mundi-technology.com or call +31-297-230840.

Source: Mundi Technology