Group of Butchers is an innovative manufacturer of meat products with facilities in the Netherlands and Belgium. Over the past few years the company has repeatedly won the ‘Indistrubutie Trofee’ award recognising the retail market’s highest appreciation of its products, so it is logical that the employees must have up-to-date knowledge and training in order to maintain such high standards.

To train its employees, Group of Butchers works with the e-learning module by CareNet. Eighteen months ago, the company formerly known as Dutch Grill Specialties (DGS) became Group of Butchers, which is characterised by craftsmanship and a traditional approach. The company has invested heavily in its new image in order to increase its appeal to various target groups – not only business-to-business activities but also towards consumers. The aim is to convince people of the high quality and authentic preparation of the firm’s meat products. The company manufactures predominantly pre-cooked and ready-to-eat products, and these are produced in five different locations: Eersel and Soest (both in the Netherlands), Oosterzele and Alken (both in Belgium) and the headquarters in Tilburg. The product range includes roast beef, bacon, various types of mince, rotisserie products, ham, spareribs, fricandeau, smoked meat, tartare, raw beef sausage and smoked sausage.

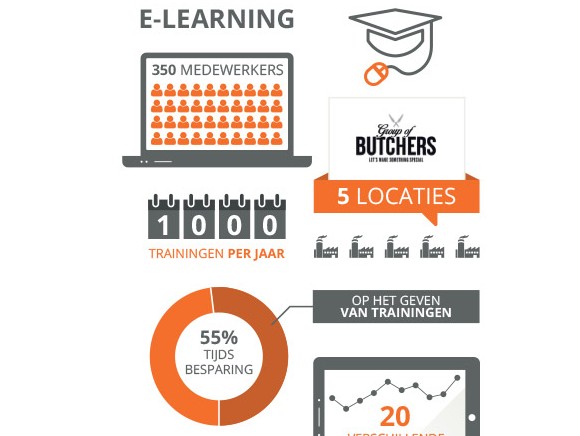

The company employs approximately 350 people across its five locations. They receive thorough training to enable them to handle and process the products correctly. The main focus of the training is on food safety and hygiene but the company culture and general information about lifting and the meanings of warning symbols are also mandatory components. Each employee does this basic training course before starting at Group of Butchers. Then at the facility itself they receive theoretical and practical training related to their specific role. The practical information is provided by experienced people such as an SVO-trained butcher. All employees also take a refresher course every year. Group of Butchers runs around 1,000 training courses annually, the majority of which are done as e-learning courses.

Max van Leeuwen is Quality, Health & Safety and Environmental Manager at Group of Butchers and is responsible for the training courses in conjunction with Human Resources. “Legislation and customer needs are changing all the time, and regular training is necessary to keep pace with this. The quickest and easiest way to provide that is via e-learning. We now provide all the theory in that way, but we still hold practical training in the workplace. Our employees can choose their own moment to do the e-learning course, whether at home, at the employment agency or at one of our locations. They react very positively to having the freedom to do so and to being given responsibility for it.” E-learning is especially ideal when new employees are hired via an employment agency. “The agency ensures that they have done the training course before they arrive at our company. That saves time because they can get started immediately. The computer system shows us whether the employees have completed the training successfully and we conduct random checks.”

In the CareNet system, Max and all other quality employees can see at a glance who has done which training course, whether they passed and which questions they got wrong. In the more intensive HACCP training courses, it is then possible to take things a step further such as by expanding on a specific topic or discussing the training with the employee concerned. “I can run analysis, such as of the most common incorrect answers or the average time taken to complete a training course.” As a further advantage Max mentions the fact that various different parties can make use of the system simultaneously, each with their own access rights. “The employment agency can add new employees and send them an invitation for training but can’t make any changes in the system.”

Group of Butchers designs the training courses itself. “I test the training course along with a number of employees before it goes online so that I can check that the questions aren’t too easy or too difficult and see whether it’s possible to finish it within the time allowed. The training courses are in continuous development and are adapted regularly so that’s a good time to make any necessary improvements too.” CareNet itself also has training courses that are related to the most common topics in the food processing industry, such as allergen management, hygienic working and cleaning. These training courses can be requested digitally. If required by the customer, they can also be supplemented by various topics or designed in the company’s own house style.

Various CareNet modules are available. In addition to e-learning it is also possible to manage an instruction manual as well as all specifications, inspections and registrations in CareNet’s secure environment. Group of Butchers uses the modules ‘manual’ and ‘specifications’ in addition to ‘e-learning’. Max van Leeuwen: “We only pay for what we actually use, which in the case of e-learning means per employee who takes a training course. That’s cheaper than the costs of loss of production time by providing classroom-based training and the associated handling costs. And what’s also important is that the e-learning training courses have been certified by auditors of the GFSI standard and hence help us to comply with the BRC and IFS standards.”

Source: © CareNet online