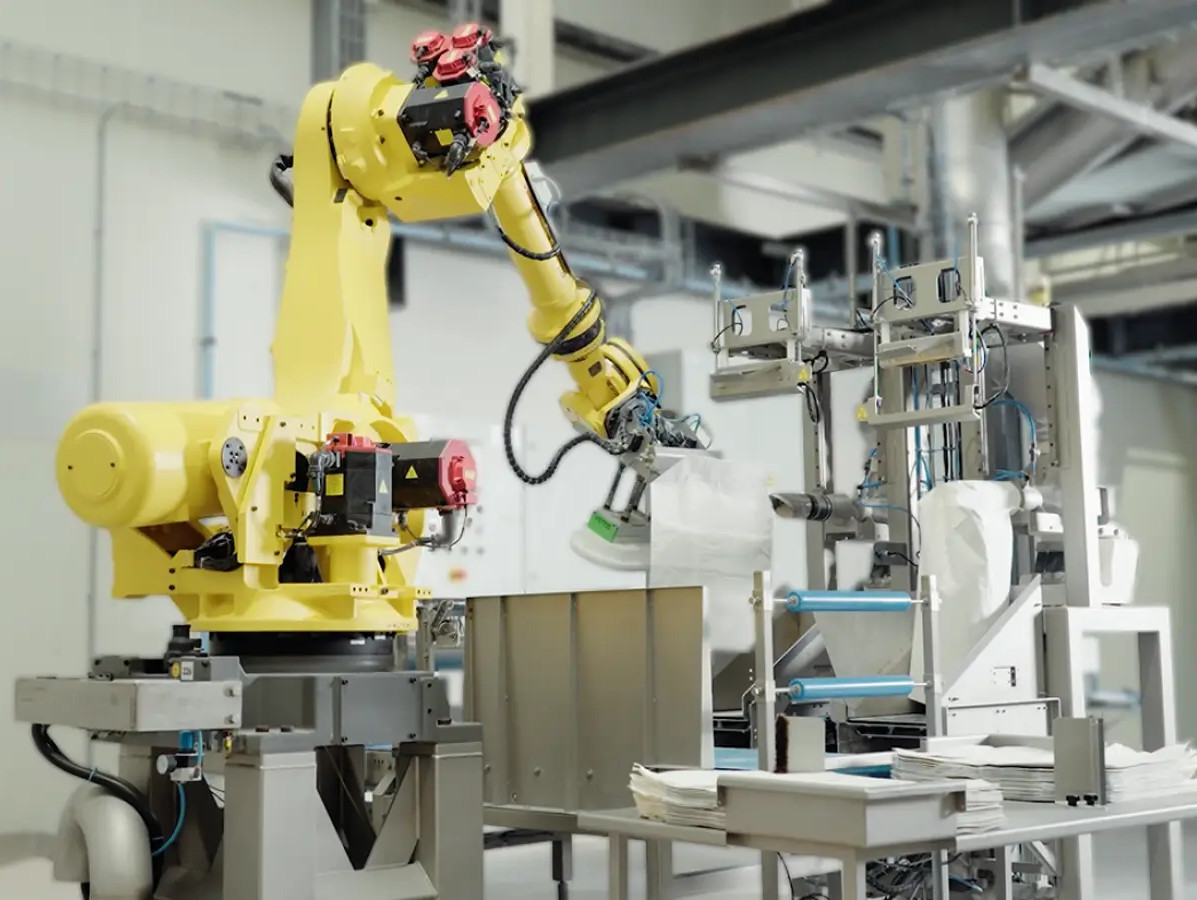

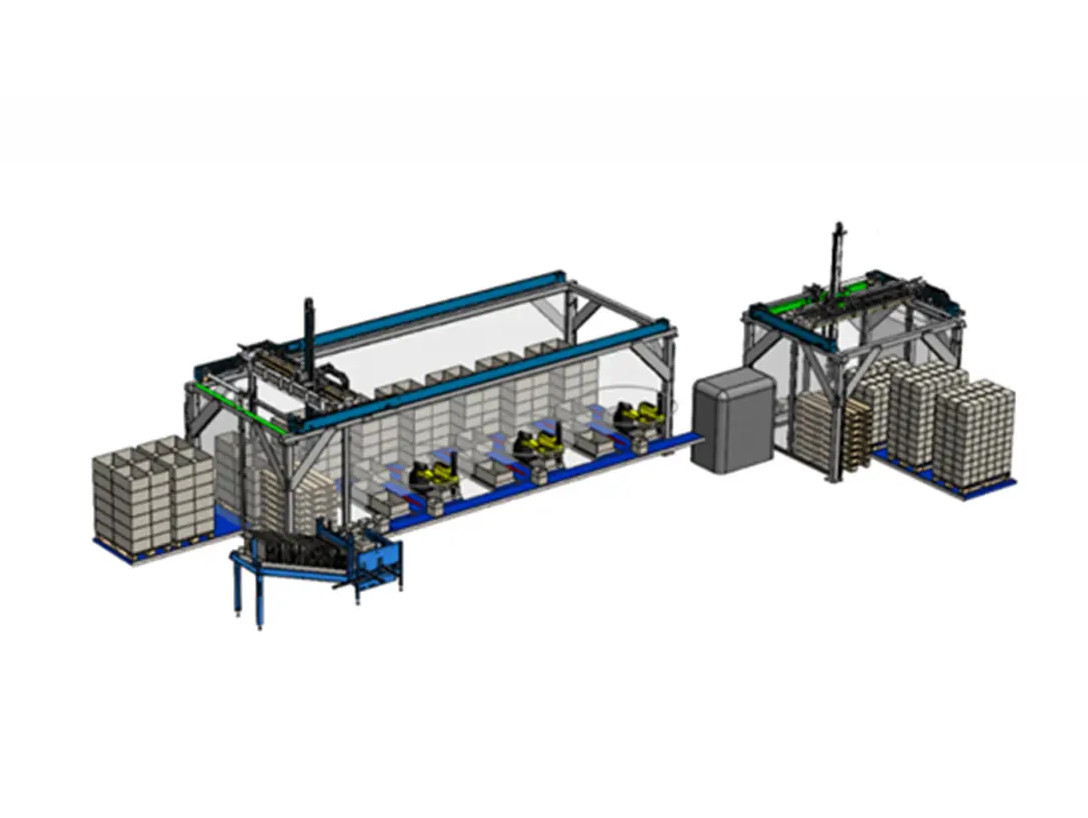

From automated palletizing of boxes to denesting (automatically separating) your product and building complete packaging lines: at VIA Techniek, we can build any machine. Whether you're aiming to reduce labor costs, increase production capacity, or gain more insight into your process, we design custom machinery that aligns with your goals.

Over the years, we've provided a wide range of bespoke machines for our clients. A few highlights:

Tailor-made machines offer a range of benefits:

We deliver the right solution in 5 steps:

1. Getting to know your process

We start with an open conversation to understand your operations and bottlenecks.

2. Defining the challenge

Together, we explore whether a completely new system is needed or if we can build on an existing one—considering costs, maintenance, scalability, and ROI.

3. Proposal & quotation

You’ll receive a clear proposal outlining the technical concept, planning, and costs. We go over everything with you to ensure full transparency.

4. Engineering, building & testing

All work is done in-house—from mechanical design and software development to electrical control. We involve you throughout the process and carry out extensive testing.

5. Installation & support

Once installed at your site, we handle commissioning, training, and fine-tuning. And we stay available afterwards—for service, maintenance, and upgrades. In case of disruptions, we’re on call 24/7.

We serve a wide range of industries, including food, chemicals, logistics, and pharma. The diverse experience our team brings allows us to apply proven, reusable technologies to new challenges quickly and efficiently.

We’re happy to help. Leave your details on our website, and we’ll be in touch as soon as possible. Together, we’ll come up with a solution tailored to your challenge. Curious how quickly your investment in custom machinery pays off? Fill in a few details on our website, and we’ll calculate your potential return immediately.

Source: VIA Techniek