Blücher found a partner with the same corporate values in Coca-Cola European Partners Nederland: high quality, sustainability, and high hygiene standards.

Eveline Bruins: "We manufacture stainless steel drainage systems, channels, floor drains, and piping for indoor and outdoor applications: from a simple bathroom to large industrial installations. Our sales markets include housing construction, utility, production industry, and shipping. Blücher is a global market leader in the area of stainless steel drainage systems. Our key accounts are mainly companies in the food and beverage industry, such as slaughterhouses and breweries." Blücher has recently become part of Watts Water Technologies Inc., but the Blücher brand name will remain unchanged.

With the proper installation of a drainage system, companies may not just save a lot of money, but also a lot of water and energy.

Eveline Bruins is Area Sales Manager Benelux with the, originally Danish, Blücher concern. The Blücher range of products (see boxed text) is both wide and deep. They have channels and floor drains in all shapes and sizes: "We always deliver customised products as every company has its unique requirements. With regard to the installation of floor drains, channels, pipes, and drainage systems, you have to take a few things into account before you start: what kind of products are involved; will they be exposed to acids during the production process; do you use glass; what is the location of the machines, what is the floor load, and what is the ultimate amount of water and waste? Needless to say that this will be entirely different for a slaughterhouse than for a brewery."

With the proper installation of a drainage system, companies may not just save a lot of money, but also a lot of water and energy. "Naturally, the costs precede the benefits, but when you don't organise everything properly from the start, it will eventually only cost money: when a drain gets blocked because it cannot handle the amount of waste, you have to interrupt the production process and this costs serious money. Prevention is better than the cure. We use our long-standing expertise to help companies in this regard. Our motto is that a drainage system has to function at least as long as the building it was installed in."

The amount of water that is being used can also be decreased with the right installation of drainage systems. Ideally, we connect the floors and the floor drains to each other for 100 per cent. Eveline: "There always is some point on the production floor where most of the waste is generated. When this waste then has to travel along a long route before it is disposed of through the floor drain or channel, it will not just cost manpower, but also a lot of water. Besides that, it is unhygienic as there is a real chance that bacteria will spread to a place where you don't want them to come during the cleaning process. A badly installed system can also cause cracks in the floor. This is not just unhygienic, but also hazardous."

One of Blücher's clients is the Dutch Coca-Cola production facility in Dongen, Noord-Brabant. Every single hour, 120,000 cans, 100,000 PET bottles, and 55,000 glass bottles are rolling off from the conveyor belts. "We continuously invest in the expansion of our portfolio, by which we respond to the changing needs of the consumer", says Claudia Biasutto, Project Manager at Coca-Cola European Partners Nederland. "In 2017, we introduced no less than 17 new beverages, and this year we can already count 21. This requires the necessary expansions and adjustments for our facility as well."

Coca-Cola has committed, on a global and local level, to important sustainability goals. Claudia: "One of the elements of our sustainability policy which we have been working on for years, is to reduce the amount of water for our production processes as much as we can. We also produce in so-called High Care Areas. Within these areas, we apply the highest possible hygiene standards. We need to do that when we want to deliver an optimal final product. We chose to collaborate with Blücher and use their products as they, just like we do, set great store on sustainability, water saving, quality, and the best possible hygiene standards."

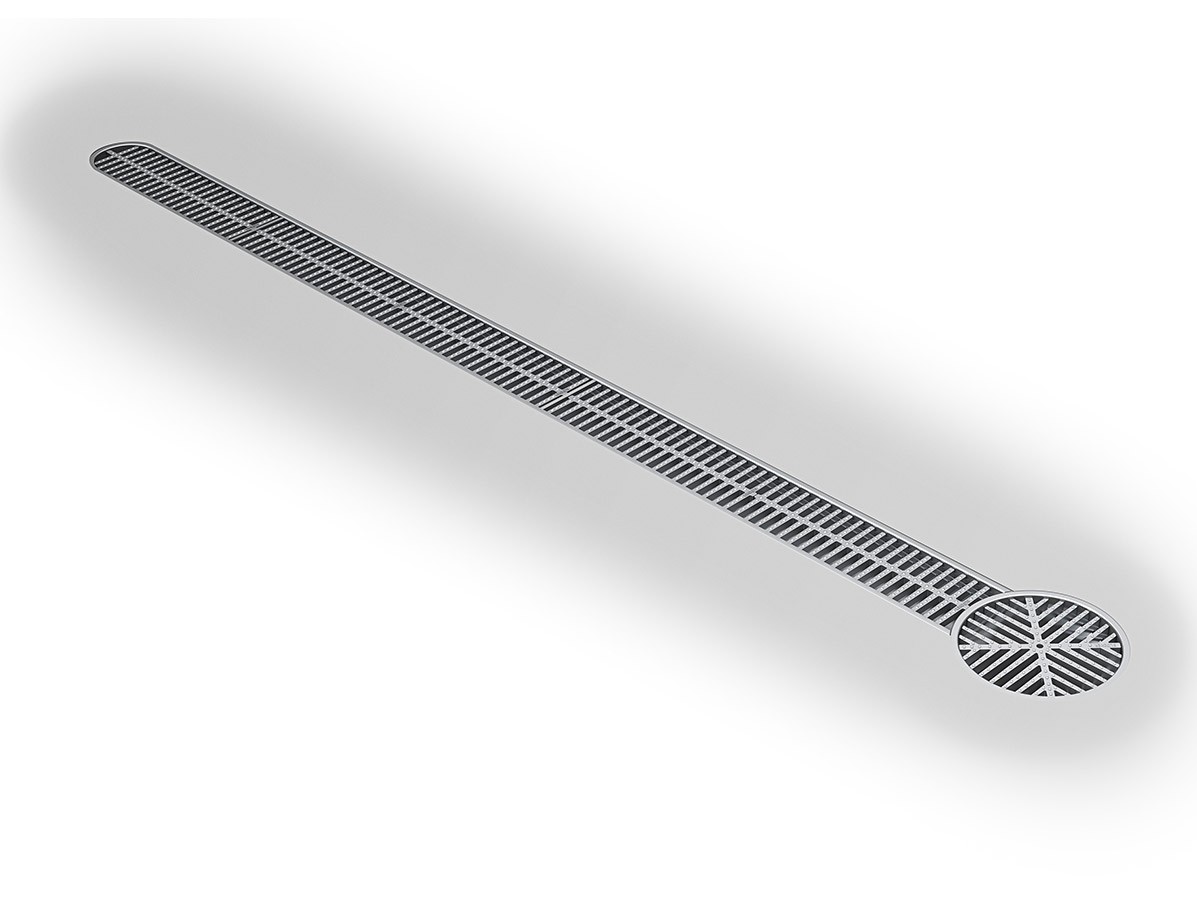

Earlier this year, a Blücher HygienicPro drainage system was installed in Coca-Cola's only production facility in the Netherlands. Claudia: "We expanded our current location this year with a new-built extension. Before the building started, we and Blücher conducted a thorough and extensive study into our requirements. One of the important issues was the heavy floor load. We work with heavy machines and, on top of that, we have heavy storage tanks. Our various production areas are also very different. We made a specification split per section. During this process, Eveline advised us about the most efficient solutions. One of them was a special wide grille in which a large amount of water can be caught at the same time. This channel is not just stable, sturdy, and hygienic, but even aesthetically pleasing. The channels had to be implemented first. They arrived in specially sealed packaging to keep them dust-free, which is essential for our production process. The entire process between engineering and the eventual construction took just 2.5 months, which was very convenient for us."

Source: Beeld: © Bert Jansen