With the peak season just around the corner, they could use some extra hands on the packing line at Berry Packing Services. That is why the super-fast Proseal Case Packer was recently purchased.

'Handle with care' is the motto for blueberries. A fact Harm Valckx has been familiar with for decades. He has run several businesses in the blueberry trade since 1997 and has been growing the fruit species since the 1980s. He now owns 160 hectares of blueberry production land in the Netherlands, Germany and Lithuania, as well as owning Berry Packing Services. There, inbound, outbound, quality control, sorting and packaging of blueberries, strawberries, raspberries and blackberries takes place.

Some 25 million kilos of fruit are processed annually at the company, which is spread across three locations in Venlo, Limburg - total area: around 16,000 square metres. About 85% of the fruit processed are blueberries. "Retailers want soft fruit in the mix; that's why we also process strawberries, raspberries and blackberries here. Those go into sales-ready packages," Harm says. He serves a large part of the European retail market. Processors (including bakeries and juice manufacturers) also buy fruit from Berry Packing Services. "When the berries arrive, they are first selected for quality, among other things; class 2 goes to the processing industry."

Dianne Bouman en Harm Valckx

Harm has seen the popularity of his product grow tremendously throughout his working life. The last decade in particular has seen an impressive increase: CBS calculated that between 2013 and 2017, sales of blueberries in supermarkets increased by 250 per cent. "Still, consumption in Western Europe is increasing by 20 per cent every year. Why is that? It is, of course, a super-healthy product," laughs Harm. He is preparing for the busiest season: the winter months: "That is our peak season. That's when the fruit comes in through the port of Rotterdam from South Africa and South America and is processed here. In spring, blueberries come from Morocco and Spain, and in summer mainly from the region. Often the berries are then already processed and packed at the grower's premises."

Blueberries from South America and South Africa arrive in containers brought under CA conditions. This involves reducing the temperature to 0.5 degrees, removing oxygen from the room and adding CO2. Fresh blueberries can also be brought under CA conditions at Berry Packing Services; they can then be stored for four to six weeks. During the winter period, it is all hands on deck. Harm: "Then all our ten packing lines are running sixteen hours a day. Some 200 people work here every day then. Fortunately, we still have enough employees for production, mainly from South-East Europe. But sometimes we do run into cultural differences, and turnover among production workers is high."

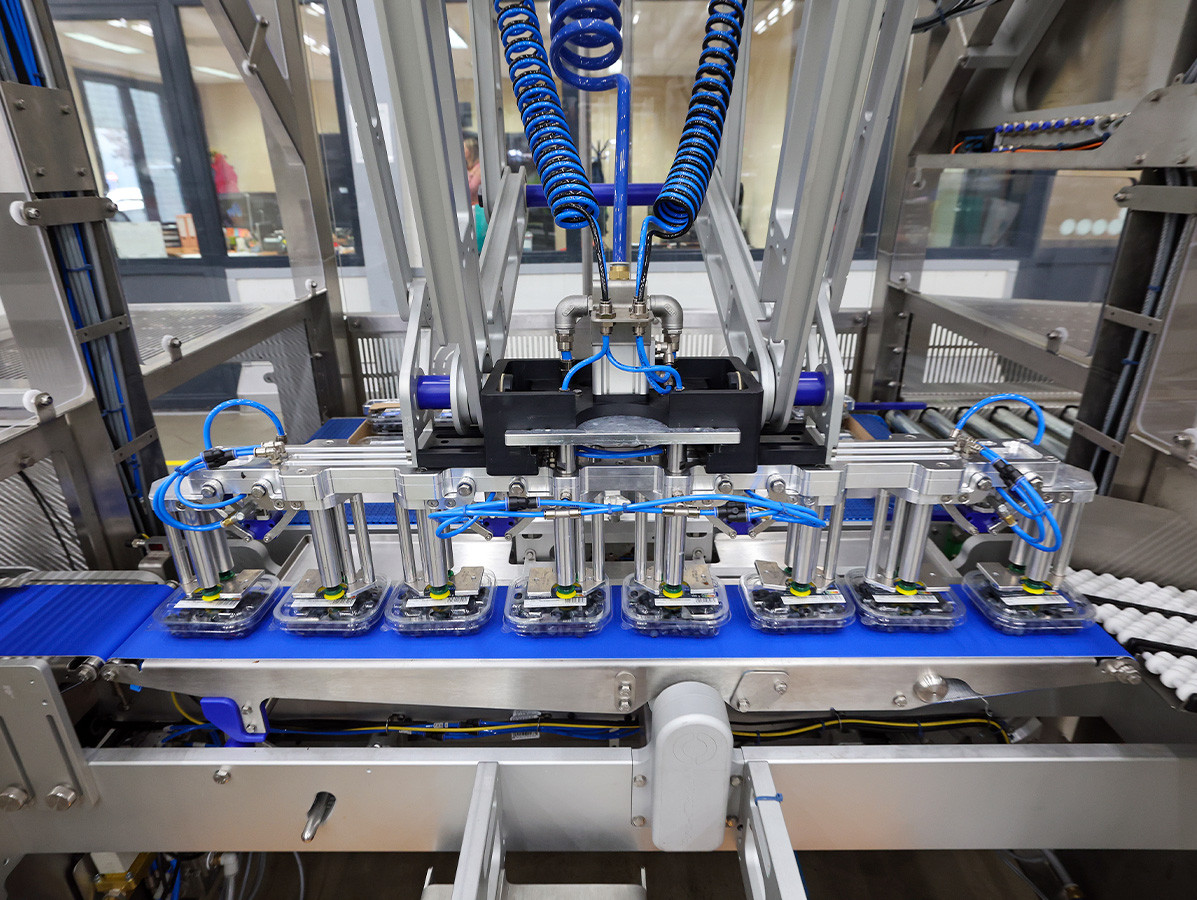

Soft fruit is a really delicate product that is quickly prone to bruising. When processing and packing, it is therefore hugely important that not too much time is lost and the fruit has few drop movements. To maintain quality and cope with rising wages, Valckx invests heavily in automation and digitalisation every year. As an end-of-line solution of one of the packaging lines, for instance, he has purchased Sismatec's Proseal Case Packer: a very fast, fully automatic packaging system for crates and boxes. Dianne Bouman, Sales Manager at Sismatec, explains: "The new Case Packer, developed together with Proseal, is the perfect complement to tray sealing machines. Its capacity is huge: the machine can place up to 160 packs per minute in a crate or box, depending on the type of machine and the pack size to be processed. In the process, it can handle a wide range of pack formats, such as trays, pails and sandwich packs - made of different materials. The user-friendly control panel makes the machine very accessible to operators." Harm is very satisfied with the machine, which has been running since the summer: "Where previously four people were standing at the line to crate the filled boxes, now only one is needed. Ideal."

Another advantage is that the Case Packer can work with any tray sealing machine, says Dianne: "It can also be fully integrated with box erectors, existing conveyor systems, labellers and coders. And the supply and removal of conveyors can be customised." Sustainability has obviously been thought of, she says: "This machine will last for years and is built in such a way that new upgrades can also be applied at a later stage." Harm expects to purchase more Case Packers in the coming years. He concludes, "Who knows, maybe there will also be a robot that places the boxes on the pallet. But we are taking one step at a time: more Case Packers first."

www.berrypackingservices.eu

www.sismatec.nl

Photos: ©Bert Jansen Fotopersburo

Source: Vakblad Voedingsindustrie 2022