It's nerve-wracking when an audit is about to take place. Quickly putting together the latest risk assessments, preparing source-cause analyses and urging the management to prepare the management review themselves this time. Most of the anxiety is felt by companies that are not quite audit-proof, or have only recently entered the circus of BRC and/or IFS food safety schemes.

Food safety schemes were originally designed to establish additional rules that a company must comply with if it produces for a supermarket organization's private label. A good initiative. It prevents the same cookie factory from getting an audit from a different retailer each week.

However, many retailers have moved away from BRC. They have created their own manuals that are even more comprehensive than the original BRC scheme. They also conduct their own audits for it. Marks & Spencer, Sainsbury, Tesco and ASDA gleefully visit again with their own auditor. It is a regular occurrence for a company to be audited every 14 days. So we are back to square one.

Whether this is helping food safety? No. Companies are unnecessarily burdened with a huge administrative burden and stress. The auditor is like a scavenger trying to note as many NCs (Non Conformities = minor violations) as possible. Which in turn creates an awful lot of work for the QA manager: he or she has to submit a CAP (Corrective Action Plan) within a few weeks. This circus hardly contributes to food safety as it ought to be ensured by the producer. However, the QESH (Quality, Health, Safety and Environment) manager gets an enormous rash because of the bureaucracy.

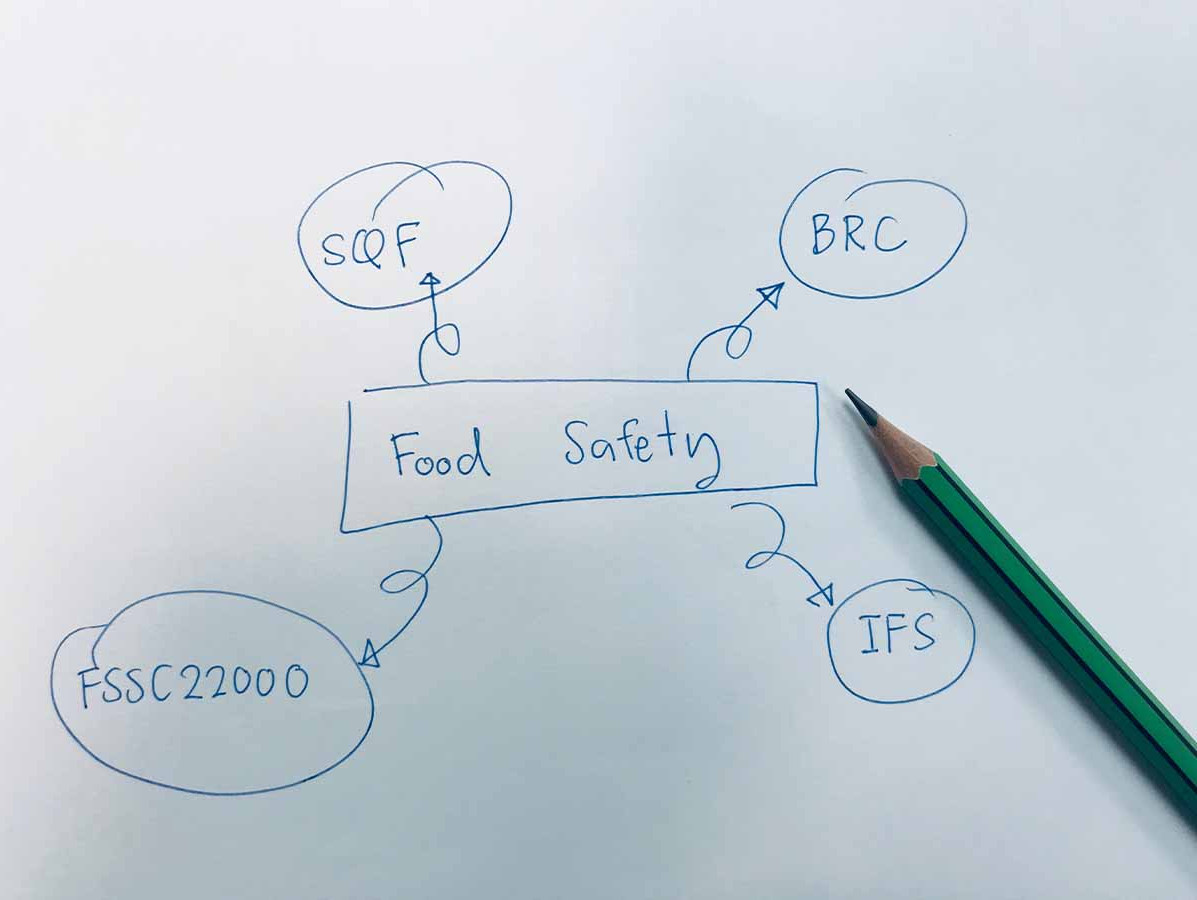

Every food producer must comply with the law and is responsible for the food safety of its products. The EU regulations are complemented by the national regulations, the NVWA provides additional information using the fact sheets. In my opinion, this is more than sufficient. The food safety schemes BRC and IFS are thus in fact totally unnecessary. Many legal regulations are casually duplicated, things are adopted from the ISO system and the schemes adopt rules from each other.

BRC-9 has no less than 325 rules (IFS-8 about 230), all of which have to be gone through and checked off. There is a regular version increase with added éxtra rules. An inattentive QA manager who overlooks these can count on penalties in the form of NCs (Non Conformities).

Those who read carefully will come across bizarre requirements. Like BRC-9 rule 1.1.6 about anonymous quality reporting. Confidential reports must be documented AND evaluated by management. Meaning that the mailbox will be filled beyond capacity! Is there no longer an external confidential contact person?

Another example concerns BRC rule 3.5.1.1 to 3.5.2.2, which describes the safety procedures (such as traceability and contamination risk) regarding 'primary packaging material'. The definition was recently expanded from the container surrounding the packaged product, to the clip holding the packaging film together. Total nonsense!

These are just two typical examples of often minor changes for which auditors receive special training. They can easily note NCs at that point. IFS is no better in this respect.

Distrust is high. The fact that even the auditor trained by the scheme owner himself is not allowed to give a final assessment of the final score at the end of an audit, which often lasts several days, is striking. That is done by headquarters. But surely a police officer does not first ask his supervisor if he can issue a fine? The competence of the auditor is completely ignored. It seems like a permanent vote of no confidence toward one's own auditors, fueled by fear of failure.

By the end of 2023, England will throw out virtually all EU regulations. In no time, this scheme will have a 100% English signature so it will hardly be in line with European rules. BRC will deny this. They are reluctant to let go of the firm and rather corrupting revenue model associated with this scheme. I expect UK retailers to promote their own private scheme even more forcibly. BRC is very insistent on using only BRC-certified suppliers. What's with the tying?

There is a solution: switch to FSSC 22,000 quickly and embrace ISO systematic thinking. FSSC 22,000 is a GFSI recognized food safety standard (not a scheme), accepted worldwide and in effect since 2005. The standard is derived from ISO 9,000 and is applicable to the entire food chain: thus including suppliers such as cold stores, transport companies, machine builders and producers of packaging materials. Companies are expected to determine all requirements relevant to them and then apply them.

The strategy used to meet these requirements can also be determined by companies themselves during the risk analysis. In the beginning it is more work to set up the handbook, but it will soon become clear that food safety is easier to ensure with this standard. A thorough audit takes place every three years. In the intervening periods only a control audit. This system has more integrity than BRC or IFS to ensure food safety. This puts a lot of responsibility on management from the beginning: it has to be solid. BRC and IFS are just schemes with a checklist. ISO includes a standard set up by the company itself, which is completely waterproofed by its own management vision.

Rules about corporate social responsibility (ISO 26000) and circular production (ISO 59020) are already included in the ISO systematics. It's a matter of waiting on BRC and IFS to copy this. I won't be surprised if they come up with the requirement for a PFAS-free statement on anything and everything. With that, another quick version-upgrade of these empty schemes can be realized.

How does the QA manager get rid of the rash?

Main photo: ©Algonga/shutterstock.com, photo text: ©Yaowalak Rahung//shutterstock.com

Source: Vakblad Voedingsindustrie 2023