This year, we can say that we have been happily contributing to cleaning in our customers' businesses for 40 years. Good cleaning obviously contributes to food safety. We design, build, install and maintain machines for cleaning companies, packaging and personal hygiene.

Not all contamination is the same. Each type of contamination requires a different cleaning approach. One type of contamination can be cleaned with hot water, while another can be cleaned with cold water. Is low, medium or high pressure required for removal? Is the use of cleaning agents necessary or not? In which way is this easy to apply? These are just some of the questions that sometimes have to be thoroughly investigated before a suitable solution can be found. That is why we regularly carry out tests, and will continue to do so.

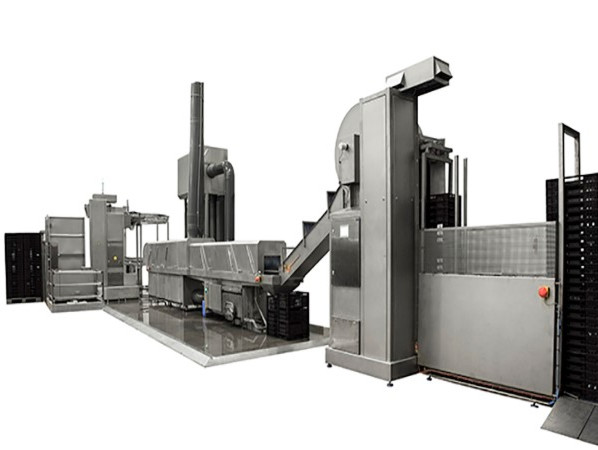

In order to arrive at the best solution, our specialist will first visit you to examine the situation. Your wishes will be discussed, as well as the various possibilities. Then, it is determined whether the solution can be found in a standard machine or a specially designed machine. After agreement, a standard, modified or completely new designed machine is built in our own workshop. We test your machine and adjust it in such a way that you get the best out of it. This way you can be sure that you get top quality solutions!

Because we work with our own installation teams, we can also take care of the complete placement and connections of the machines. Complete water, air, gas and cleaning lines are provided for you. In order to guarantee quality, we are certified water and gas technicians. So from machine to installation, you only have to deal with one party.

The machines are designed in such a way that they can be operated with a minimum of personnel. Especially with the crate washing lines, you can therefore make considerable savings in personnel costs. But with the machines, you can save on more fronts, our specialist will be happy to explain this to you!

Everything for a satisfied customer!

Source: LETS BV