Using a new method to measure the texture of materials, scientists of Wageningen University & Research are helping the food industry to improve the texture of meat-replacing products.

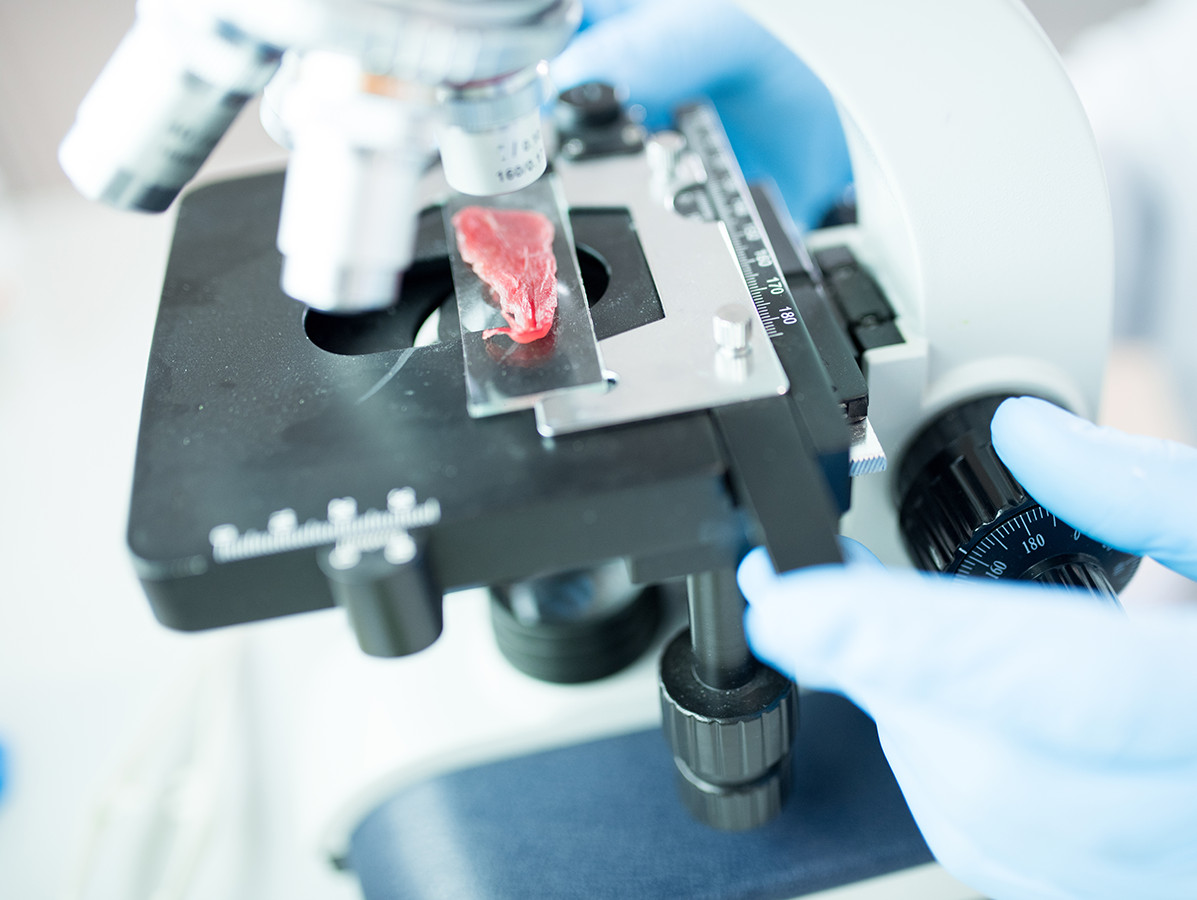

The acceptance and success of meat-replacing products depends not just on their price and flavour. To a large part, it has to do with their texture – in other words, the sensations they evoke in your mouth when you chew them. Food technologists worldwide are trying to improve the texture of their meat analogues. But how do you measure texture? Sven Boots and colleagues at the department of Physical Chemistry and Soft Matter were the first to develop a quantitative method to compare local mechanical variations between meat and meat analogues. They published their results online in the Journal of Food Engineering.

Meat replacements are made from eggs, nuts, lentils, beans, seaweed, fungi, wheat and a range of other base ingredients. “With this increasing demand, there is an increasing incentive to improve the quality of these products”, says Sven Boots. “Mimicking the texture of real meat turns out to be quite a challenge. To do so, you need to be able to measure it.”

Texture in meat-replacing products, as Boots explains, has to do with their mechanical structure. “These products are mainly made from proteins”, he says, “which are cooked to form fibres, which in turn make up bundles. An important factor for mechanical structure is bundle size. This depends on the protein composition, but also on processing parameters such as temperature, salt content, and mixing rate.”

To test the mechanical structure of the finished product, Boots and his colleagues designed a system that pushes down on meat and meat analogues at evenly spaced places. “We call this multi-point indentation. It allows us to spatially measure the local stiffness”, explains Boots. “Local stiffness varies between products, like chicken, beef, pork, or various meat analogues. It determines the resistance you feel when chewing these products. The variation in this resistance, or how it is distributed spatially, determines the texture you perceive when you chew.”

These data are then turned into ‘mechanical maps’, which are analysed quantitatively using a correlational method also used in fields like criminology and geography. “With our method, industry will be able to link the variation in stiffness to various process variables, such as temperature, salt, and protein content”, says Boots. “They can use this link to optimize their production process towards meat analogues with a mechanical profile that resembles meat.”

In the spring of 2021, the Wageningen researchers will start a follow-up study to determine how this works in practice. They also aim to link the outcomes of their work to the actual experiences of test panels. This could pave the way to the method’s application in the food industry. Boots: “It’s hard to say how long that will take. In the meantime our work is useful from a fundamental perspective.”

Source: Wageningen University & Research