A collaboration between Dyson and industrial hygiene manufacturer Elpress resulted in the development of a hygienic, fully integrated hand washing and drying solution. It’s already been installed in some of the most hygiene-conscious environments.

As a supplier of specialist hygiene room equipment to the food manufacturing industry, Elpress prides itself high standards in workplace hygiene. They’ve been working with Dyson for many years.

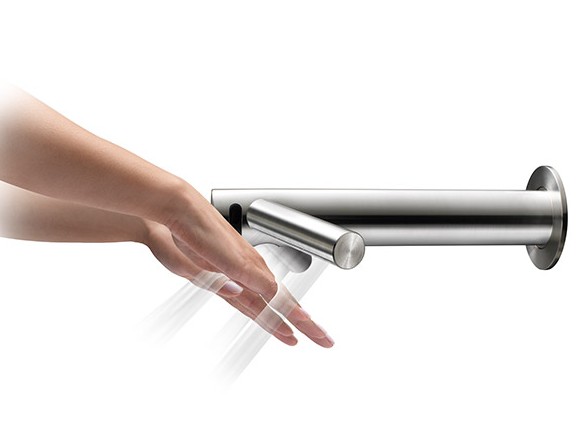

Now, with Dyson’s development of fast, hygienic hand drying technology in a tap, Elpress has integrated the Dyson Airblade Tap hand dryer into its hand washing stations.

Hands are washed and dried above a stainless steel sink. There’s no need to move to a separate drying area, so no water is dripped on the floor – lowering the risk of slipping and improving health and safety.

When hand washing and drying take place in separate areas of the hygiene room, queues and bottlenecks are common. With an integrated solution, the hand washing and drying process flows more smoothly and efficiently – saving time and improving productivity.

The Dyson Airblade Tap hand dryer is sensor operated, so hands don’t touch any contaminated surfaces. It also uses a HEPA filter that captures 99.9% of particles the size

of bacteria from the air used to dry hands. So hands are dried with cleaner air, not dirty air.

A growing number of major food manufacturers trust Dyson to play an integral part in the hand hygiene process. These include Kellogg’s, Alpro and the Dutch cookie manufacturer, Merba. After installing 10 Dyson Airblade Tap hand dryers across two washing stations, positive feedback by staff has led to the expansion of Airblade™ technology across the business.

“ We were looking to avoid water on the floor by replacing paper towels – so an integrated at-sink washing and drying solution was ideal.”

Wim Boerman, Director, Merba.

For more information:

Telephone: +31 (0)485 516969

E-mail: [email protected]

www.elpress.nl

For calculations visit www.dyson.co.uk/calcs

In collaboration with Carbon Trust, Dyson has produced a method to measure the environmental impact of electrical appliances and paper towels. The carbon calculations were produced using GaBi software provided by PE International, based on product use over 5 years and using the US as a representative country of use. Dry times for products

were evaluated using DTM 769.

The Carbon label is a trade mark of the Carbon Trust. The NSF logo is the registered trade mark of NSF International. HACCP International non-food certification mark is the registered trademark of HACCP International. HACCP International have certified Dyson products based on their recommended installation and operating conditions. Licensed by Dyson.

Source: © Dyson en Elpress