The concept of food packaging is ‘as old as the hills’. Evidence from ancient times shows that, even then, people had devised ways of making it easier to transport food and keep it fresh for longer.

Empack, the Netherlands’ packaging trade fair, takes you on a journey – from earthenware pots and nettle leaves via the first tin cans to biobased packaging.

Prehistoric man wanted to be able to store his grain, pulses, meat, fish and fruit for longer periods. In fact, it was essential in order to survive barren winters. First of all, the ingredients were dried thoroughly, such as in the sun or over an open fire. The food was then placed into earthenware pots. The pots were sometimes covered with a layer of fat from slaughtered animals because people had discovered that it created an airtight seal, and that stopped the food from rotting. And there were other smart solutions too. People realised that nettle leaves slowed the rate of decay caused by bacteria and in prehistoric times the leaves were used as packaging for butter, fish and meat.

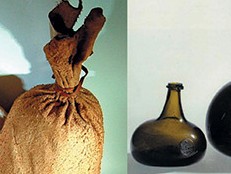

Glass probably originated in the ancient cultures based around the Mediterranean. In the Middle East, enamelled objects and jewellery items have been found dating from around 5000 BC, and in and around 2000 BC glass was used to make ointment bottles, vases and jewellery in Ancient Egypt. Even so, glass jars were not used to store food until around 1200 BC. In the second century BC food was wrapped in bark from the mulberry tree in China and its pulp continues to be used to this day to make high-quality paper.

China is the birthplace of paper as we know it. The first paper to be produced in Europe was made in 1144 in Xativa (close to Valencia) in Spain. Until the 19th century, paper production was small-scale and artisanal but things started to move quickly following the launch of the first commercial cardboard box which was produced in England in 1817. On 1 November 1871 in New York, A.L. Jones applied for a patent for ridged paper for packaging purposes: corrugated cardboard. The first pre-cut and foldable cardboard boxes were invented in 1890, and a new industry was born. Branding, labels and logos were introduced between 1866 and 1870. Twinings Tea of England is regarded as the oldest logo and it clearly has a good shelf life because it is still in use today!

The process for making tin-plated steel was discovered in Bohemia (Czech Republic) in the year 1200 and sealed tin cans were first patented in 1810. Metal and plastic became increasingly popular from 1970 onwards and the first packaging suitable for warm food was launched in 1980. But all that packaging created an economic headache: what should be done with all the waste? The late 1990s saw the first step towards biobased packaging with specific attention on biodegradable packaging used for fruit, vegetables and soil. Nowadays, a growing number of companies are investing in fully biobased production.

Tetra Pak is currently one of the world’s largest players in FMCG packaging with an annual revenue of 11 billion euros. In 2015 the firm won the Packaging Europe Sustainability Award with ‘Tetra-rex’, its fully biobased packaging, and it has set itself the goal of achieving 100% biobased production by 2020. In the coming years, there will be an increased focus on the efficiency and life cycle of packaging. HAK’s upright pouch for vegetables is a good example of this. The transition from glass jars to upright pouches has several benefits: the pouch is lighter, easier and cheaper to transport and it takes up less space too.

One of the major challenges associated with the growth of e-commerce is how to package the products. Whereas consumers used to walk into a store, buy what they needed and carry them home in plastic bags, under new EU rules introduced in January 2016 retailers are no longer allowed to give away free plastic bags. But that pales into insignificance compared with the other challenge: shipping products ordered from webshops. What does that mean in terms of logistics? How should products be packaged for safe transport and to ensure they arrive with customers in good condition?

Objectives such as to achieve a more efficient approach to the available space in boxes (put simply: more pouches than jars fit into a box) or to use lighter packaging materials to reduce transport costs stimulate innovation, such as the ‘Foodmailer’. This transport packaging concept has been specially designed for specialists in fresh ingredients or meal boxes as well as retailers who want to sell their fresh products online. The transport packaging comes with paper ice packs which enable retailers and e-tailers to keep their fresh products optimally chilled in transit to end customers. Thanks to the accompanying app they can calculate precisely how many ice packs are required based on the product volume, the ambient temperature, the transit time and the desired product temperature on delivery.

'From the past to innovation'

“Consumers still shop online as if they are in a physical store. If their mindset changes, there are lots of gains to be made,” says Stefan Hermsen, lecturer in food packaging at HAS University of Applied Sciences. “Vegetables, for example, stay fresher for longer if they are stored in a dark place. Light damages vegetables, so transparent packaging isn’t the best option. They will retain their freshness for longer in opaque packaging, but consumers need time to get used to that idea. In another example of packaging concepts which may require Dutch consumers to adjust, products such as apple sauce or wine, traditionally sold in glass jars or bottles in the Netherlands, are also sold in cardboard cartons abroad. Such products are either simply not available in cartons in the Netherlands or they are regarded as ‘cheap’ and hence ‘poor quality’ (in the case of wine). That perception will most likely change eventually, partly thanks to the sustainability factor.” Empack is focusing heavily on the very latest advancements in packaging, including for e-commerce.

Source: Illustratie: ©aarisham/Shutterstock.com