Do you want to purify food, or detect contaminants in water at breakneck speed? Then microfiltration is extremely useful. The Dutch company Aquamarijn has developed a new type of micro sieve, 90 percent more economical than conventional sieves.

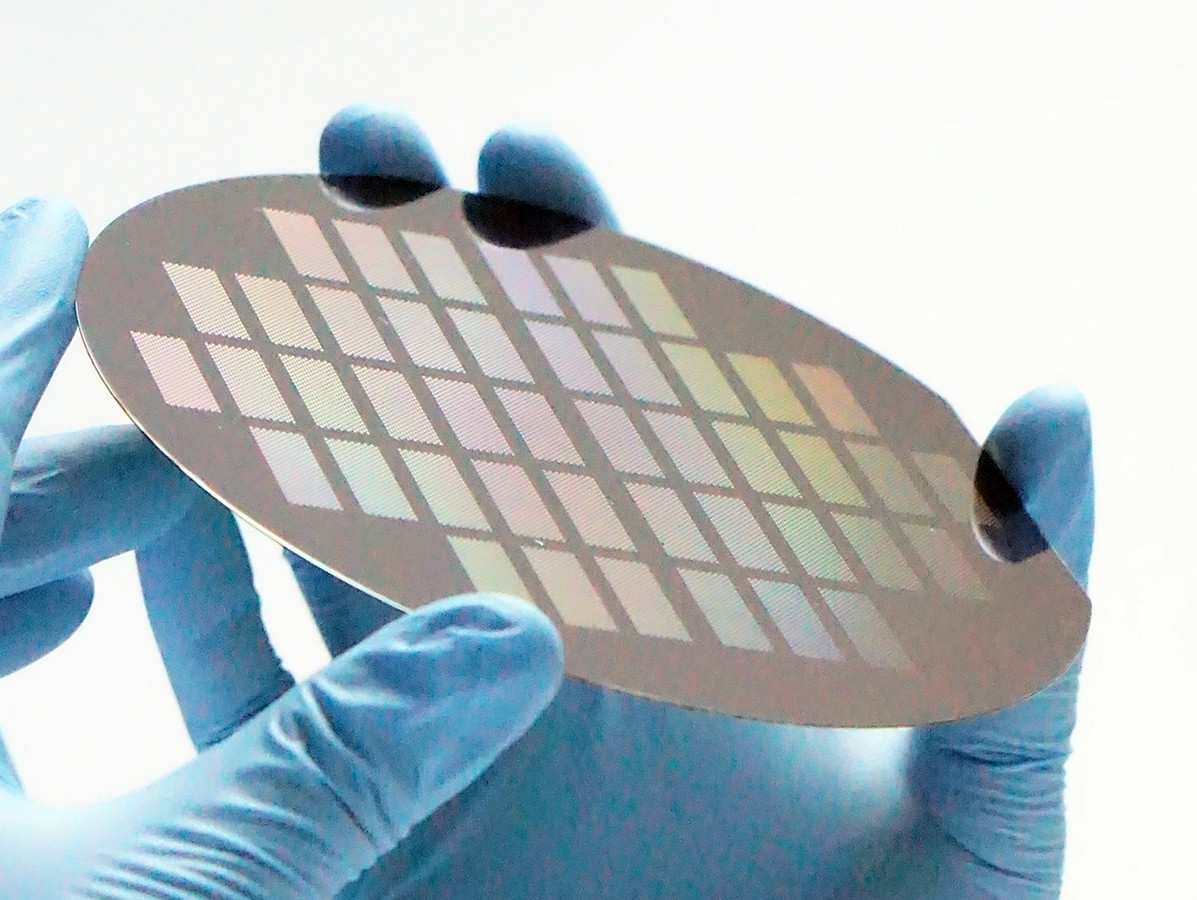

"The ceramic microsieves we make contain extremely thin membranes that can filter particles from liquids at micro level," says Jacob Baggerman, Principal Scientist at Aquamarijn. "Think of microorganisms, such as bacteria, found in water, dairy or blood. These kinds of unwanted particles do not pass through the artificial pores in our membranes and therefore get stuck in the sieve". Twenty years ago, the company already carried out projects with companies such as Grolsch and Friesland Coberco. "They use membranes because they are capable of processing large quantities of liquid. The disadvantage of conventional membranes is that they are relatively thick. There has to be a constant high fluid pressure on the filters to guarantee sufficient flow. This is a very energy-intensive process. Microscreens can very quickly filter a lot of fluid at low pressure and are therefore less energy-intensive. Unfortunately, this also causes them to clog up quickly. The challenge is to keep the sieves clean".

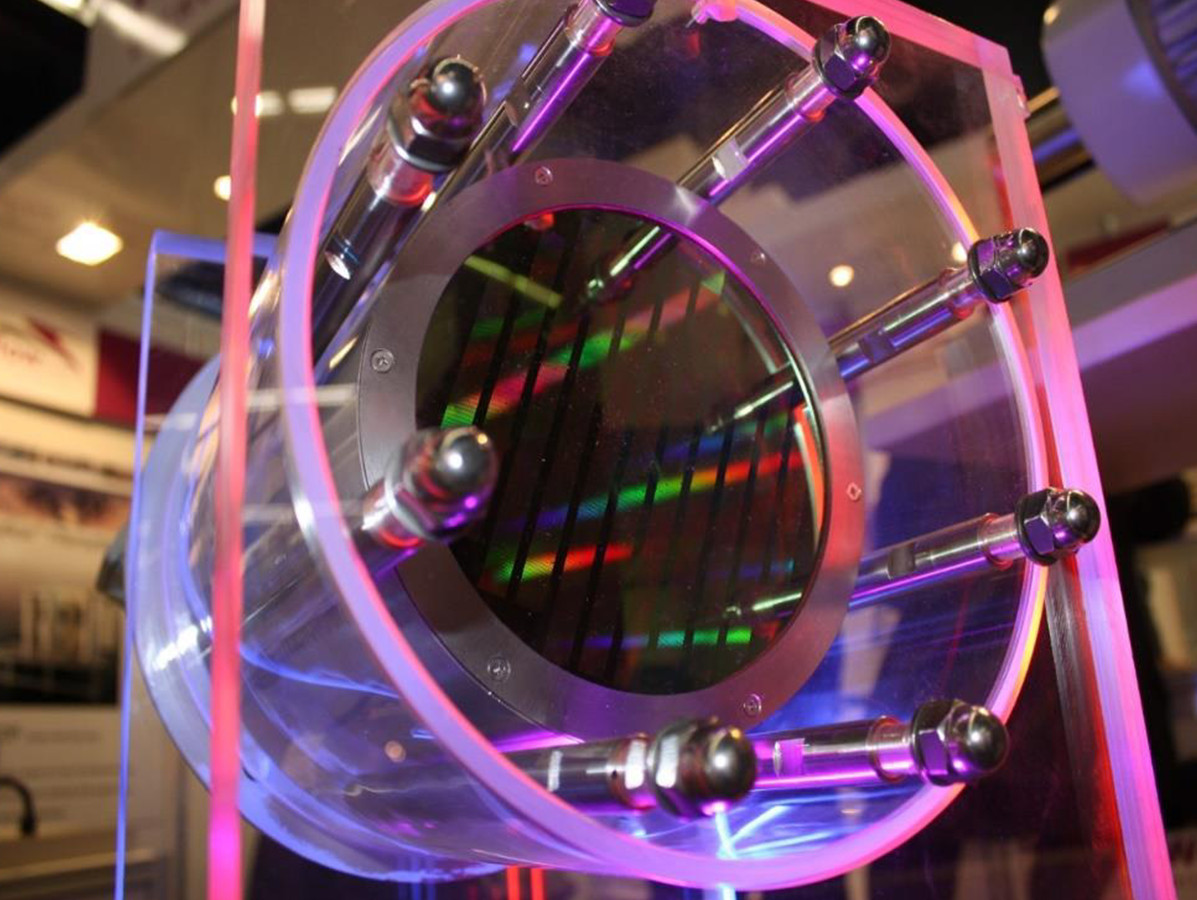

"Around 2015 we found a solution for the rapid pollution of microsieves," Jacob continues. "At that time, we ran a project with a Swiss company. They already had a lot of experience with rotating membranes. They liked it so much that we set up a joint venture with them. Together we came up with another way to keep the sieves clean." Instead of a stationary filter that stays clean through movement of streams, the partners developed a rotating filter; microsieves in a rotating disc. " A sort of vacuum cleaner is directed at this disc," Jacob says. "At each rotation of the disc, that vacuum cleaner sucks the membranes clean. It's an efficient system that consumes very little energy compared to conventional membrane filtration. No more energy is needed to maintain flow pressure, just to rotate the disc. Per 1000 litres of liquid we have therefore gone from 39 to 5 kilowatts per hour. A reduction of almost 90 percent."

In order to get the application of the new microsieve technology off the ground, Aquamarijn received a subsidy from the Rijksdienst voor Ondernemend Nederland (RVO). The collaboration with the Institute for Sustainable Process Technology (ISPT) was also decisive for the success, according to Jacob. "Thanks to them, we came into contact with our project partners DSM and NIZO. DSM helped us demonstrate the technology with an attractive business case; employees of NIZO made a calculation model in which they calculated how much energy and money savings are possible if you apply this technology in an organization". Jacob and his team want to bring the new microsieve to the market in a few years time. "Our technology works and is scalable. We know what we need to focus on to make the microsieve more attractive. For example, by reducing the investment for customers. Subsidies from the government can be a solution."

"The energy transition is not our first motivation to work on this technology," Jacob admits, "but we are proud that we can contribute to large-scale energy savings. The fact that we are helping to achieve the objectives of the Climate Agreement does mean something to me. The thing I really like is that our product - in addition to saving energy - also serves other social goals. For example, doing rapid microbiological analyses, blood analyses for cancer cells and gas-free atomisation of liquids. It's fantastic to make that kind of impact as well".

By 2050, the Netherlands will have to emit 95 percent less CO2 compared to 1990. By 2030 there should already be a 49 percent reduction. That is stated in the climate targets. On the basis of these targets, the government imposes requirements on industrial companies. It supports them in meeting those requirements - with knowledge, networks and subsidies.

New subsidies

Through the Rijksdienst voor Ondernemend Nederland (RVO.nl) it offers various new subsidies. Unique and one-off are the subsidies Demonstration Energy and Climate Investment (DEI+): Circular Economy and the Accelerated Climate Investment Industry (VeKI). These subsidy schemes contribute to the accelerated achievement of the CO2 reduction targets of 2030. In 2020, a whole new type of scheme will also open, supporting innovative integrated solutions for industry: the Emission-Driven Research Development and Innovation (MOOI) scheme.

This subsidy is specifically intended to shorten the payback period of CO2-reducing investments. The central government has released 28 million euros for this subsidy.

Conditions: Projects must in any case revolve around the themes of 'energy efficiency', 'recycling' or 'reuse of waste'. It must involve investments in proven measures, with a payback period for the investment costs of more than five years. And the application of the project must be ready for the market. This means that the application must be proven at least three times in comparable projects in Dutch industry. Applications for VeKI can be submitted to RVO.nl until 30 June 2020 (no later than 17.00 hours).

This scheme is specifically designed to support integrated solutions that contribute to the climate targets. The central government has released 65 million euros for this subsidy, of which 17 million euros are specifically for industrial solutions.

Conditions: Projects eligible for the MOOI scheme must have a substantial financial volume. The exact size is yet to be determined. In addition, the project must clearly have an integral approach. For this reason, several companies in the innovation chain must be affiliated to the project. These are preferably organisations from different disciplines and consortia. It is also important that applicants draw up clear milestones in their plan. These must be SMART (Specific, Measurable, Acceptable, Realistic, Time-bound), so that progress can be closely monitored.

RVO.nl helps you further. Via its subsidy and financing guide you will immediately find out which subsidy for CO2 reduction your organisation is eligible for. You will also see how you can make use of RVO.nl's knowledge and network.

Source: © RVO