The Dutch use approximately 26 billion plastic food packaging per year and the trend points to a further increase. However, if consumers reduce their use by five packs per year, this could halt growth. This is the conclusion of an analysis by the ING Economics Department. Food producers, supermarkets and specialist shops also have a major role to play. There are several ways to achieve better packaging by reducing the amount of material and making smart material choices. None of these are fully capable of solving the various problems associated with plastic on their own. This requires a combination of solutions.

The calculations of the ING economists show that the Dutch use 26 billion plastic food packaging per year. For every Dutchman, that means more than 1,500 pieces per year and about four per day. Plastic contributes to the shelf life, food safety and ease of use of products, making it the most widely used food packaging material. The food sector therefore accounts for a large proportion of total plastic consumption. Of the more than 500 million kilos of plastic packaging material that is put on the Dutch market every year, more than 40% is intended for food and beverages.

If nothing changes, the total number of plastic packaging in the Netherlands will continue to rise. Population growth will lead to an increase of approximately 100 million units per year until 2023. In addition, the use per person will increase because more pre-processed fresh products, small packages for single-person households and convenience products for on the road are purchased

The key to change lies partly in the hands of the consumer. If consumers were to reduce their annual use of plastic packaging by five, this could halt the growth in the number of plastic packaging. For the total to actually shrink, at least a reduction of more than five pieces per Dutchman is required. To achieve this, consumers will have to give up a bit of convenience."

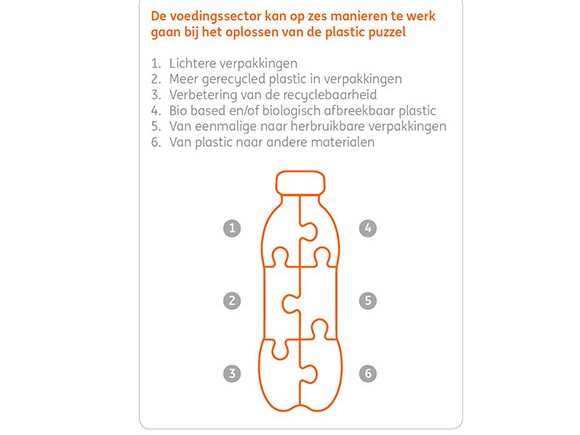

Food manufacturers and retailers can work towards less plastic and better plastic packaging in several ways. An often used way is to use lighter packaging. For example, the weight of some bottles has fallen by half in fifty years. There are also opportunities in the use of recycled plastic instead of new plastic, the transition to bio-based plastic and the use of reusable packaging. In addition, changes to the design and type of plastic used can promote recycling. Each and every one of these ways will help to reduce the environmental impact of plastic and reduce dependence on oil and gas.

Ceel Elemans ING Sector Banker Food & Agri: "There are several ways to break the upward trend. They all know their limitations. Bio-based plastics, for example, are relatively expensive and many types of plastic do not yet have a recycled variant on the market that meets all food safety requirements. In order to take steps, companies will have to combine several ways."

A large majority of the respondents in the ING Question of Today (64%) said that plastic was the least sustainable packaging material. On the other hand, glass and cardboard are seen as the most sustainable, partly because of the longer tradition of separate collection and the fact that a larger proportion is ultimately recycled.

If there are problems with the use of plastic, why are food manufacturers not more likely to choose tinplate, cardboard or glass for their packaging? Although other materials can sometimes provide a solution, switching often does not solve all the problems. For example, similar glass or can packaging generally requires more material and energy than plastic. Among other things, this does not benefit CO2 emissions.

"Plastic packaging knows its shortcomings, but giving them up completely brings with it new practical problems. For many fresh food products, there are hardly any alternatives that can match plastic in terms of food safety, shelf life, functionality and price. Reducing the amount of new plastic needed is therefore the most effective step now," says Ceel Elemans.

Source: ©ING