“I find the current crunchy muesli packages unwieldy. The product is in a plastic bag that cannot be resealed, which is inside a cardboard box. Personally, I think it’s really irritating when I have to pour the contents out into a storage container or get to work resealing the packaging with clothes pegs. Sometimes, the bag tears completely apart when I open it. I started this project because I, as a consumer, was frustrated with the current packaging.

If my “Click” concept is produced, it has to be of PP with an EVOH layer in between to serve as an oxygen barrier. PP has the advantage of high flexibility without tearing or breaking, which means that the clicking system

can constantly be closed and opened again. The click system has to be made via injection moulding. In order to make this mould once, investment is required.

During the Food Experience, I received many positive reactions to my concept from people who sympathised with my frustrations and found it to be a useful solution. I am passionate about structural and graphic design. This year, I am graduating from the Packaging Design programme and I am eager to work in that field.”

“My reason for coming up with this concept was my mother’s illness: early onset Alzheimer’s. When she told me that she ruined her apple pie before she even put it into the oven, I said: ‘But mum, just buy the apple pie mix.’ She said that was what she did. ‘How can that go wrong?’ I wondered. I hadn’t really thought about it, but cooking is complicated: you have to plan and portion things out, so you’re multi-tasking. For instance, people with mild intellectual disabilities or autism have difficulty with it.

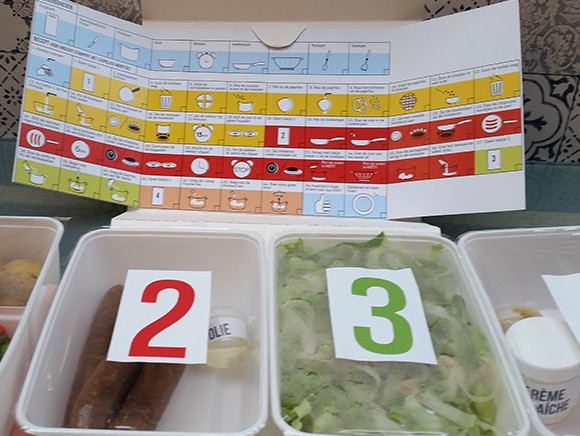

How do I package various ingredients in such a way that they are laid out on the counter in the right order, come in a compact package (both in the refrigerator as well as on the counter) and include an easy-to-follow recipe that describes every single action required, step by step? And how do I make this logical, useful and easy to produce? That was a huge challenge.

The Headless Chef meal package is like a compact toolbox that you open up on the counter. The ingredients are divided into four plastic trays and an outer cardboard package houses the trays. Each tray is colour coded with the steps in the recipe, which are primarily pictograms. All the necessary steps are included, even getting a knife and a cutting board.

The Food Experience blew me away. There were so many positive reactions and personal stories from people who knew someone that this concept would be a solution for. The most interest came from the healthcare industry and packaged meal producers. Since then, I have been discussing the concept with Ondernemers Lift+ Brabant. If the packaging is produced, I would try to focus on using more sustainable materials: recycled cardboard and trays made of biobased plastic. I want to continue developing this concept and seek out a collaboration with a meal service or a producer.

“I regularly see my grandmother fumble with the packaging of pre-packaged meats. She is not the only one. Due to having less strength or precision, or a pull tab that is difficult to get a hold of, people with arthritis, rheumatism or decreased mobility have trouble opening these packages. A knife or scissors are often needed to get them open. That was something I felt could and should be done differently. I am someone who is eager to help others. This was a topic that I was happy to put everything I had into for 20 weeks.

The biggest challenge was to come up with packaging that could be opened by everyone and at the same, retained the efficiency of the packaging process for the meat goods producer. Ultimately, I came upon the idea of packaging that could be opened in multiple ways. The pull notch at the top is easy to grab, so scissors are no longer necessary.

My packaging solution is still a prototype at the moment. The thermoform outer packaging is made from the same material as the current packaging and the upper film is not yet suitable for production. More research is required into finding the right foil that does not tear if the consumer exerts too much force when pulling at the notch.

During the Food Experience, I received many positive reactions, from the business community as well as from consumers. A number of parties expressed interest in collaborating or further discussion of the concept. In February 2019, I will have graduated and am eager to get to work. However, I also want to continue developing and growing in my field, so I will definitely take courses. I may even go for my master’s degree.”

“Frozen pizza is primarily purchased because it is quick and easy to make. In my opinion, the current packaging, a cardboard box with a plastic sleeve around the pizza, could be much more convenient.

PizZO consists of a cardboard tray with a plastic top seal. The packaging can be opened with one movement and the pizza can go directly into the oven in the tray. This keeps the oven clean. The pizza is pre-sliced and the tray serves as a plate, which cuts back on dirty dishes.

The tray can be sorted with paper goods, while the seal can be thrown in with cans and plastics. Both the tray and top seal are freezer safe and prevent the pizza from drying out.

The tray is also heat resistant thanks to a special food-safe coating. This coating ensures that the cardboard can handle the high temperatures in the oven. A frozen pizza baked in the PizZO packaging will be just as crispy and delicious as a pizza made according to the current preparation method. Premium brands can distinguish themselves better on the shelves with this packaging.

I received many positive responses at the HAS Food Experience. I am eager to continue developing my packaging and looking into other potential uses. I am still looking for producers who can help me with this. After I graduate from the HAS University of Applied Sciences, I will go for my master’s in order to deepen my knowledge of innovation. I really enjoy coming up with new packaging ideas: concepts that are truly useful for the consumer.

Iris and her packaging concept won the Foodmanship Award for the best Smart Challenge.

During the 10th edition of the HAS Food Experience on this past 30th January, over 200 fourth-year students at the HAS University of Applied Sciences presented their innovations and solutions for today’s food challenges.

No less than 7 degree studies showcased food-related projects from the graduating year, so it was an inspiring exposition overflowing with young talent. The Dutch Food Industry Journal was really impressed with these four innovative packaging concepts.

Source: © Vakblad Voedingsindustrie 2018