In Cuijk, Danone Nutricia has been producing high-quality baby food for over 100 years. Six kilometres away, at Bedrijvenpark Laarakker in Haps, Danone Nutricia built a new ultramodern and sustainable factory on 8.4 hectares of land. With the possibility of expansion in size and capacity.

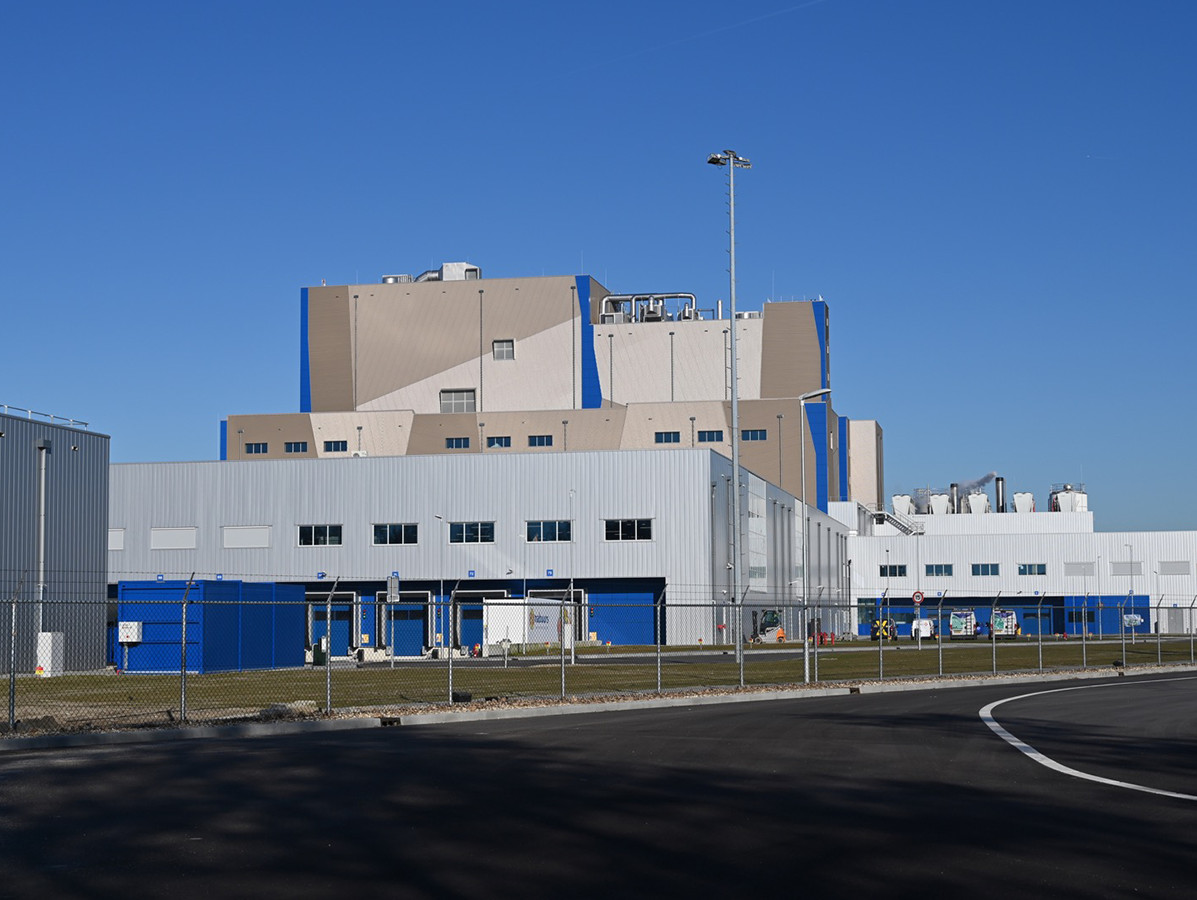

There is a great demand for high-quality, specialised products from the Netherlands. Danone is therefore market leader and wants to remain so. The company invested 240 million euros in a new factory in Haps. The result is a location with a double production capacity compared to its factory in Cuijk. Where the latest technologies are used to make 600 different products. Where sustainable goals are realized. On a business park where agrifood is in charge. Along the A73, you can't ignore it. On 13 February, members of the OSV were given a glimpse of this factory.

Why did Danone Nutricia choose to build her new factory in Haps? As factory director Haps/Cuijk Sijmon Hage told during the company visit, the Cuijk branch had reached its limit. In order to be able to grow, produce greener and innovate, a new location was needed. The Laarakker business park in Haps was developed in 2007. A business park that offers the agrifood sector interesting business opportunities. Director of Bedrijvenpark Laarakker Olaf de Croon, who was present at the company visit as a member of the OSV, explains: "Our region is a leader in the field of (agri)food technology and innovation. Our business park offers plenty of opportunities in this sector, with an easily accessible location and sufficient staff. Above all, we meet the need for growth opportunities for regional entrepreneurs".

Danone was one of the first companies to make the switch to Laarakker and took the opportunity to develop a new, larger location close to 'home'. Moreover, because of the move at a limited distance, she was able to retain her employees and thus her knowledge and skills. From a social and economic point of view, this was an important precondition for continued growth. Danone is not the only one who innovates close to home. Olaf de Croon is pleased to announce that wholesaler Holland / Verbruggen Food Group is also moving to Haps because of growth. "The company is currently based in Mill, about 8 kilometres from Laarakker. The construction of a new 60,000 m2 distribution centre will start soon, with completion in 2021".

Danone is very pleased with the cooperation with the municipality of Cuijk and Bedrijvenpark Laarakker. In consultation, the location along the A73 was chosen. The company and the municipality shared their thoughts, advice and development plans. Olaf de Croon: "We strengthened each other in the process. We want to unburden our customers, for example, we helped Danone with the application for permits".

The factory is standing and a piece of land has already been bought next to the factory. For growth. The factory is modular, so it is relatively easy to build an extra module in the future.

The factory produces baby powder. A product to which the highest environmental, hygiene and safety requirements apply. Not surprising when you consider that babies live 100% on these products the first year. According to the requirements of ISO-certifications an audit takes place 20 times a year. The baby food is tested about 600 times, from delivery of the product to delivery to the market. A tour of the factory, for example, is not possible; this can be risky. That's why a walk-through was made right at the time of construction, giving visitors a glimpse of the factory and its history through windows, videos and timelines. The tour teaches visitors that the factory is fully specialized in conventional baby food and specialties for cow's milk allergy and reflux. A total of 600 different products are made, exported to 90 countries, feeding 35 million babies every day. Production runs from the wet part - from raw material to powder - to the dry (packaging) part. The surface area of the factory is twice as large as in Cuijk, there is three times as much spray-dry capacity and twice as much packaging capacity. The number of employees has remained the same. Each area is only accessible with an access pass for those employees who are allowed to work there and are dressed according to regulations. Technology determines, cameras supervise. Dust accumulation or other contamination is prevented as much as possible. This has been taken into account in detail during construction and furnishing. For example, employees store their personal clothing and bags in lockers with sloping 'roofs', so that no stuff can be placed there on which dust can settle.

Sijmon Hage's presentation to OSV members tells us that originally, over 100 years ago, Nutricia and Danone were separate pioneers in health. Fifteen years ago, they joined forces through a takeover of Nutricia by Danone. The mission has remained the same ever since the companies were founded: 'health through nutrition for as many people as possible'. For 1.5 years now, that mission has been supported by the slogan: 'One planet, one health'. The operational management is completely dominated by this slogan, the footprint is kept as small as possible. The construction of the new factory therefore had sustainable objectives: 100% renewable energy, 60% less water consumption, 50% less CO2 emissions. And social objectives such as 'I am safe'. According to Sijmon Hage, the first 1050 days in the new factory are over without an accident involving absence from work. According to the benchmark in the Netherlands, an average of 10-15 accidents occur in such a time frame. I am safe' also means looking at each other, always holding the handrail and parking the car in reverse to be able to drive away with better visibility. For Danone, safety also means that Laarakker consults with its immediate neighbours. These should not pose a risk to the production of baby food. "Olaf de Croon adds: "Think of odour-producing companies that can influence the fermentation process. "We will keep in close contact about this. This is not a problem for our park. The agrifood sector is diverse. A logistics partner could be a good neighbour".

www.danone.com

www.laarakker.com

On February 13, 2020, the OSV visited Danone Nutricia. In cooperation with Bedrijvenpark Laarakker, the company visit started with a pleasant lunch provided by the students of ROC de Leijgraaf. Want to know more about the OSV?

www.osvnetwerk.com

Photos: Airphoto © Danone, others: © Laarakker

Source: © Vakblad Voedingsindustrie 2020