We're currently searching through more than 4,000 articles, just a moment's patience...

We're currently searching through more than 4,000 articles, just a moment's patience...

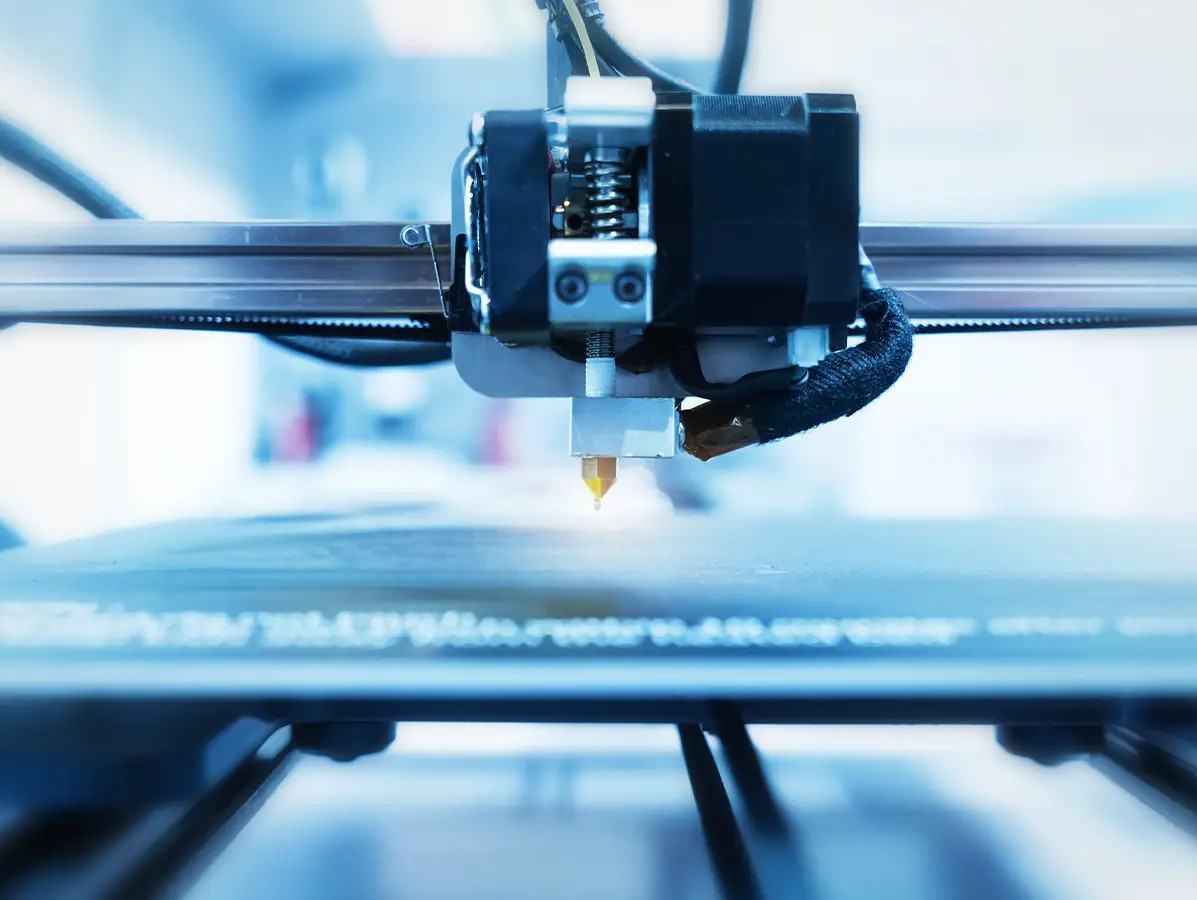

Royal Avebe is working with TNO and Wageningen University & Research on an innovative method for producing plant-based meat alternatives: 3D food printing. Using potato starch as a base, the cooperative is exploring how technology and ingredients can reinforce one another.

“Our starch potatoes are rich in starch, protein and fibre,” says Annet Vrieling, application specialist food at Avebe. “We can process these into raw materials that remain liquid or become firm and gel-like.” These properties make the starch highly suitable for new applications such as printed food. With this, Avebe aims to shape the future of food—both literally and figuratively.

According to Vrieling, 3D printing opens up new possibilities in structure and presentation. Think of fish-like textures that are difficult to reproduce using traditional methods, or products that differ entirely from what's currently available. “We want to build the expertise to create products that are not only technically sound, but also tasty and appealing to consumers.”

Avebe, TNO and WUR are working together on the entire development process—from protein structure and dough behaviour to scalability and mouthfeel. “Every element matters, so there’s a lot involved,” Vrieling notes. The latest 3D printer from TNO is easier to clean and supports higher production speeds. The next step is factory testing. “Food is a global challenge. This innovation has the potential to make a difference worldwide.”

Source: TNO

Vakblad Voedingsindustrie is a project of b2b Communications BV.

© COPYRIGHT 2025 VOEDINGSINDUSTRIE | ALLE RECHTEN VOORBEHOUDEN

Powered by Wallbrink Crossmedia © 2025

Een abonnement kost € 80,- exclusief 9% BTW per jaar.

We work in accordance with the privacy legislation. After your registration you will receive an e-mail with a confirmation link. Only after you have clicked on this link will you be registered as a recipient of the newsletter. If you can't find the e-mail in your inbox, please also look at unsolicited e-mail.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec